Table of Contents

How can we make sure that the quality & specification of our hookah coals are the same in each container? Coconut Charcoal Briquettes Quality Control – 7-Step Process for Wholesale Shisha Charcoal Buyers

Our coconut charcoal factory works hard on quality control and implements an extensive 7-step inspection process throughout the production of hookah coal.

We operate in-house and third-party independent laboratory testing that ensures that we consistently produce high-quality coconut charcoal briquettes for shisha with an ash content of no more than 1.6% and a burning time of 2+ hours. Also, we keep our Fixed Carbon level at 85-92%, so it makes our shisha charcoal odorless and burns a long time with very high heat

Not only laboratory and field tests, but our charcoal factory is also certificated with ISO 9001 the international Standard for Quality Management.

To make sure our wholesale hookah charcoal buyers can sell our product and enjoy a quality shisha smoking experience, it’s essential to check for several key parameters when selecting shisha charcoal.

All those parameters are being constantly checked by our Quality Control factory team.

Again, we have a dedicated team for QC who checks parameters during all production processes. Starting from accepting raw material (coconut shell charcoal): check Fixed Carbon (should be 87% up, ideal 92%), and tapioca (tested for odor, by keeping it 24 hours heated in the closed bottle. If after 24 hours there is no smell – this tapioca is ok for use in production).

If you want to read more about how to check the quality of hookah coals you can check in the article.

First, we check Odorless and Sparkless: Using odorless and sparkless coconut charcoal for shisha is crucial as it ensures that the charcoal does not emit any unwanted smells or sparks during use.

Discover the highest quality coconut charcoal for hookah with our coconut charcoal factory. Our 7-step quality control process and in-house and independent laboratory testing guarantee an ash content of no more than 1.6% and a burning time of 2+ hours.

Discover the highest quality coconut charcoal for hookah with our coconut charcoal factory. Our 7-step quality control process and in-house and independent laboratory testing guarantee an ash content of no more than 1.6% and a burning time of 2+ hours.

Most importantly free from smell. It is the main reason why coconut charcoal is being used for hookah coals.

The reasons why shisha charcoal can smell you can read in my article here. If you have no time to read it – just remember that a high level of carbonization, good tapioca and strict following to the production processes will keep your charcoal safe from smells

Second, Long Burning Time: A longer burning time of over 2 hours ensures a longer-lasting hookah smoking experience without the need for frequent coal replacements. Our cube of 25 mm can stay up to 2 hours 15 minutes, Cube 28 can last up to 2 hours 45 minutes.

For long burning it is very easy – just do not mix your coconut charcoal with wood. Why are other factories mixing it with wood? Simply to cut the costs. Wood charcoal costs 1/4 of the price of coconut shell charcoal.

That is why – be aware if someone proposes you cheap charcoal. It can be mixed with wood.

Third: Low Ash Content: Low ash content leads to higher temperatures and a better taste of shisha tobacco.

We maintain the starting burning temperature at 650 – 750 Celsius. A high and stable burning temperature helps to keep the hookah smoking experience consistent, with no dips in temperature affecting the flavor and smoke output. Again, it is extremely important to keep a stable high temperature while smoking shisha

Forth. Strength and Durability: It is essential that the coals are strong and do not crack or break if dropped, to ensure a stable and consistent smoking experience. No crack on the charcoal, no need to replace it.

Our coconut charcoal is odorless, sparkless, strong and durable, with a low ash content for a better taste. Join wholesale buyers and enjoy a quality shisha smoking experience with our product from Indonesia, expertly guided by Greg Ryabtsev.

To whom this article is:

This article has been written to provide valuable insights and information to wholesale bulk buyers of coconut charcoal for shisha who are considering purchasing the product from our factory in Indonesia, with the aim of reselling and distributing it within their respective countries.

The composition of this article was carried out under the expert guidance of Greg Ryabtsev, a renowned authority in the field of coconut charcoal.

How do we check the quality of coconut charcoal briquettes

In-house quality control team

Our coconut charcoal factory has a special team for checking the quality of our products. Before someone joins this team, they go through a 3-month training. After training, they take an exam and must pass it in front of the production director, production manager, and factory owner.

For example, Mr. Gatot Wibowo, the Head of Production personally examines our quality control team members, to make sure everybody understands our standards. Especially, shisha charcoal is a very sensitive product, so some parameters like smell and fill of smoking can be checked only by experienced shisha masters.

We have three teams for checking charcoal quality: one checks the raw coconut shell materials, another checks during the production process, and the last one checks the final product and packaging. The head of the team is

The team that checks during production works in a lab on the second floor near a meeting room. This way, our customers can come and see the quality control process for themselves.

Independent quality control with laboratory

In addition to our in-house quality control measures, our charcoal undergoes regular assessments from an independent quality control laboratory to verify the quality of our coconut charcoal briquettes.

This helps us to cross-check and calibrate our laboratory. We send some of our charcoal to this lab once a week to double-check and make sure our own quality control is accurate.

It helps us to cross-check and be sure that our charcoal briquettes are according to the standards.

The laboratory conducts thorough tests to determine the ash content, moisture level, calorific value, and volatile matter of the charcoal.

7 steps quality control process

Our quality control consists of 8 steps in an in-house quality control procedure that includes:

1. quality check of raw material (moisture, ash content, ash color, carbonization level, volatile matter) -coconut shell charcoal

2. quality check of meshed material (size of mesh, density of mesh)

3. Pre-mixing and post-mixing quality check on ash color and ash content

4. Extrusion stage we do a quality check for viscosity, density, stretching, compression, elasticity, hardness, flexibility, brittleness

5. Cutting stage: we check the size of briquettes, irregularities, the roughness of the product, ash content, and ash color

6. Pre-oven and after-oven stage: we check moisture, ash granule content, ash content, ash color, self-reheating capability, burning time, start temperature, end temperature

7. After packing quality check with an independent laboratory and random check after 1-week of packaging for the final product

The raw material of coconut charcoal shell check

First, our quality control team is checking raw materials. We use only natural coconut charcoal shells. It is a natural product that can naturally vary in its properties.

Depending on the region coconut was grown, the season (wet or dry season) of coconut charcoal shells can be very different.

Our factory operates its own charcoal-burning facility on Halmahera Island, but due to high production volume, we have to buy some additional coconut charcoal shells from independent farmers.

That is why we have been 100% sure that all coconut charcoal shells are good and according to our factory standards.

One key aspect of quality control for coconut charcoal briquettes is ensuring that the raw materials used are of high quality.

This includes selecting coconuts that are free from mold or rot, as well as ensuring that the charcoal used in the briquettes is pure and free from contaminants.

Besides it, we checked the carbon value content to make sure it burned perfectly.

We check:

- moisture,

- ash content,

- ash color

- Carbon value

- Calorific value

After coconut charcoal is checked by the QC team it is delivered to our crushing facility at the second production unit.

The second production unit is located 500 meters from the main production factory. Coconut shell charcoal is being checked, separated, and screened.

We operate industrial grade 8 and 12-meter-length, automatic screeners. It helps to keep charcoal clean from any dirt other than charcoal materials.

After screening, the raw material is crushed and becomes a powder. By the way, our QC is also checking and measuring mesh size, to keep it constant.

Production stage quality control

After crushing and becoming a mesh the coconut charcoal goes to the production line.

Coconut charcoal is mixed with water and tapioca.

Another important aspect of quality control is monitoring the manufacturing process to ensure it is carried out correctly.

This includes checking the temperature and pressure used during the briquetting process and monitoring the final product’s moisture content.

The production stage includes Mixing, Extrusion, Cutting, Breaking, and Drying processes.

On all of those processes, we check:

- Moisture

- Burning Temperature at the start

- Burning Temperature at the end

- Ignition time

- Reheating capability after the flame dies without oxygen

- viscosity,

- Density,

- stretching,

- compression,

- elasticity,

- hardness,

- flexibility,

- Brittleness

The very important part is to check the shape and size of the briquettes. If we produce a cube, it should be a perfect-shaped cube with 0.5% volatility in the angles.

Same with the size of coconut charcoal briquettes should be the same size as all charcoal briquettes and the proportion of briquettes.

The very important part is the weight of the briquettes. It should be according to the specifications and factory standards

Gas oven quality control check

One of the critical parts of production is the drying process. It is made in a gas oven. Each oven can carry 2.5-3.5 tons of charcoal.

After the oven, we make Drop Test or fragility test to know how strong is the charcoal. It is important to have strong charcoal briquettes to keep them from falling apart if it falls down.

During the drying process, we control the temperature, moisture, and hardness of coconut charcoal briquettes.

We are using 4 gas ovens that allow us to control the exact temperature.

There are many factories that use wood or wood pellets. They can make a cheaper product, but they cannot guarantee the quality as we do with gas ovens.

Packaging Stage Quality Control

Besides production very important to control the packaging. Make sure your charcoal is packed clean and tight.

We check the printing quality of the master boxes and inner boxes. Make sure all colors, gradation, cutting, and glue are the same and good.

Loading to container

Before loading the boxes of coconut charcoal briquettes into the ocean container, we take the time to clean each box.

This ensures that you receive clean boxes when the shipment arrives. We also mark each row of boxes with the number of boxes in it. This helps us keep track of the exact number of boxes we are loading and ensures that we load the correct amount.

This attention to detail and thorough process helps ensure that our clients receive high-quality coconut charcoal briquettes.

Packaging of hookah coals on the tables

One of the ways to make sure your clients receive shisha charcoal and more from you is to give them “clean” charcoal briquettes. Clean – meaning that it does not leave dust on your hands.

Have you ever experienced that after taking shisha charcoal from the bag your hands become black because of the dust? Well, our factory is making really clean hookah coals.

We pack our charcoal on special tables with wire grids that allow all dust and dirt to fall down to the ground while packing only clean and nice charcoal.

Also, we have additional bright lamps in the area of packing to make sure our packing team can see each individual charcoal briquette and manually (visually) check if it is in good shape and has no spills or impurities.

So this is manual check ensure your customers will enjoy clean and nice charcoal without dust and with clean hands.

Also at our factory, we have a dedicated packing area that is located separetly from the main production area.

This helps to prevent dust from production and the coconut shell storage area from going inside the packing.

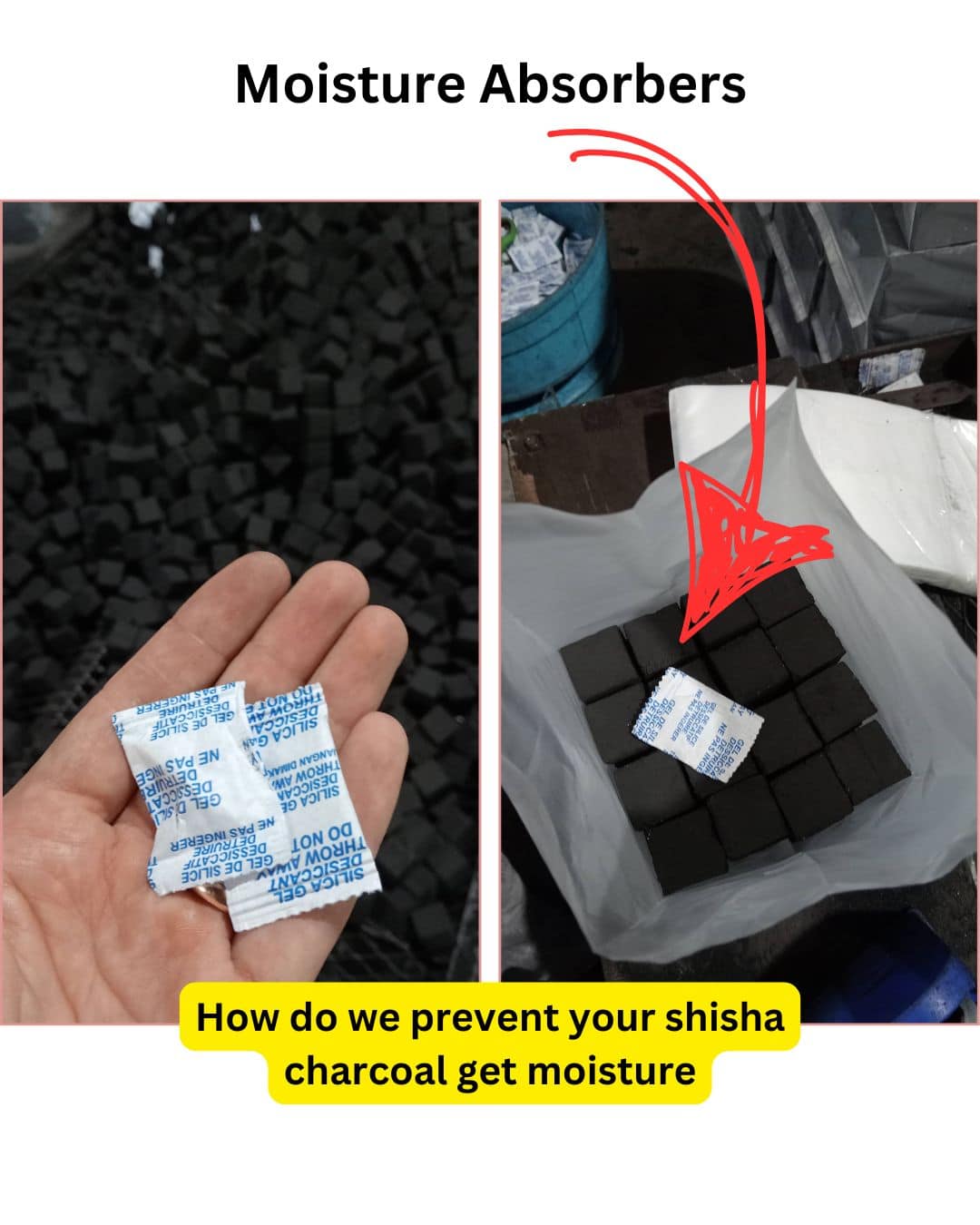

Moisture protection for your packaging with shisha charcoal

We also very care about moisture protection for the shisha charcoal. As our factory is located in Indonesia and most of our customers are in Europe, the USA and the Middle East it takes time to deliver goods.

That is why we make sure your shisha charcoal is well protected from moisture.

In each individual pack (we called it inner plastic) we use silica gel as moisture absorbers.

For 1 kg inner plastic we use white silica gel (food grade) 1 gr. While for bulk packaging we use 5 gr white silica gel.

By the way, we can do customs branding for the silica gel too. So you can put your brand on it

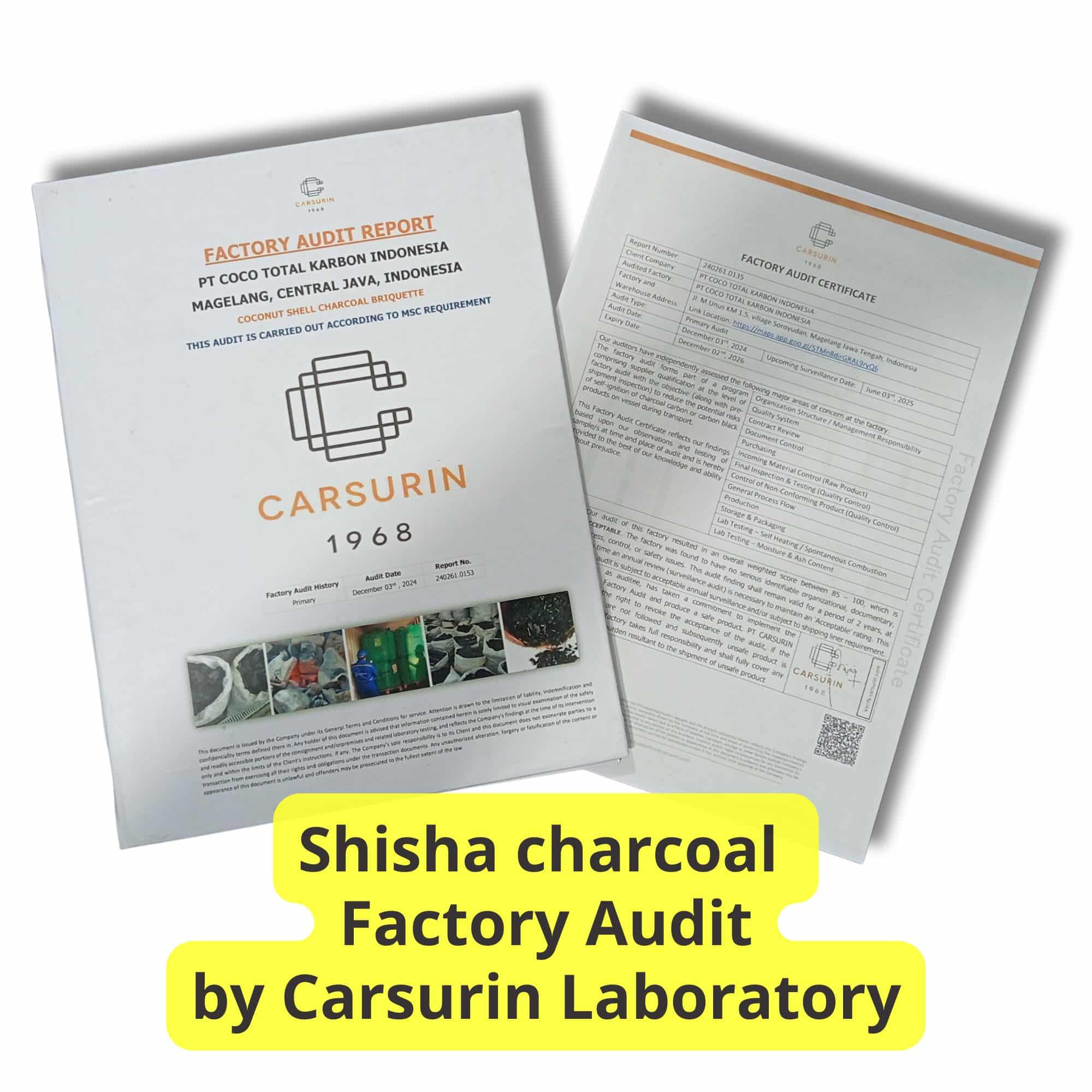

Factory audit by independent surveyor

Factory Audit is an important document for all shisha charcoal factories. It is made by independent surveyor and laboratory. Our factory has two Factory Audits from Carsurin and Backjorindo.

Factory Audit (FA) is to prove that the hookah coals factory is working according to the standards and operates according to the SOP. Meaning that all manufacturing, packing, and other processes are analyzed and written.

Factory audit is also required by shipping lines. For example, MSC shipping lines only accept Factory audits from the Carsurin laboratory.

Without FA you cannot book a container or ship shisha charcoal outside of Indonesia.

Factory Audit is issued and has to be reviewed and renewed each year.

It is very important to make sure that your charcoal factory obtains FA otherwise you cannot export shisha charcoal.

Or have to work “under the name” meaning exporting using other factory names (actually it is prohibited by shipping lines).

The thickness of the molding. How to get the perfect shape of the hookah coals

This is very often missed by most of the factories. However, the thickness of the extruder molding is very important to make a perfect and very sharp shape for the briquettes.

Most of the factories are using simply wired extruders that move slightly during the production process. It makes the hookah coals get a slightly defective shape.

At our factory, we use thick solid laser-cut extruders that make perfect shape and size. For sure it costs more, but the results are good and stable.

In conclusion,

The article describes the quality control measures in place for the production of coconut charcoal briquettes for hookah coals.

Our coconut charcoal briquettes factory in Indonesia has an in-house quality control team, as well as regular assessments from an independent laboratory, to ensure that the charcoal has an ash content of no more than 1.6%, a burning time of over 2 hours, is odorless, sparkless, strong and durable, and has a low ash content for a better taste of shisha tobacco.

The raw materials are carefully checked, including the coconut shells which must be free from mold or rot.

The 7-step quality control process includes checks at various stages of production and a random check after 1-week of packaging for the final product.

The article is aimed at wholesale buyers of the product.

The best coconut charcoal for shisha is made by Greg Ryabtsev at PT Coco Total Karbon Indonesia. If you are interested in purchasing coconut charcoal, please visit www.charcoal.pro to check prices and specifications.

What are the blinking spots inside the shisha charcoal briquette?

Very often I am asked what those blinking dots inside of the shisha charcoal briquette are, is it tapioca?

No, it is not a tapioca – it is the granules of the coconut shell mesh.

After the carbonization process, we grind charcoal shells into the small granules.

So if you break your hookah coal briquettes into two parts inside you will see those granuls. If the granules are big and very well carbonized (meaning your Carbon level is 85% and up) it will be blinking in the sunlight.

So in general – more blinking dots inside your charcoal briquettes is better, as it has a higher carbon level.