Table of Contents

How To Choose Coconut Shell Charcoal Briquettes Factory for Shisha & Hookah

There are more than 30 coconut charcoal factories in Indonesia and thousands of coconut charcoal traders. How to choose the right one for your products? There are two main issues with charcoal factories: quality & production time. Basically, the first-time order is usually best for quality, but the next order can become very different.

Keeping good quality charcoal is the biggest concern for all buyers. The problem is in the specification of coconut shells. Different batches of coconut shells bring different quality. For example, coconut shells from Sumatra make charcoal ash become browner. While coconut shells from North Sulawesi keep ash white.

The quality of coconut charcoal also depends on the way of coconut shell drying and burning. If the coconut shell was dried under the sun up to 15% of moisture content. Then coconut shells burned with pyrolysis (ie without oxygen) – the quality will be good. But on the other hand, if shells were not dry enough and burned in the forest with oxygen – the charcoal will be low quality.

Young coconut shell is also not good for producing high-quality coconut charcoal. Only old sun-dried coconut shells are the best choice to make charcoal. One more important parameter that can influence charcoal quality – is mixing shells with soil and wood. Sometimes wood and soil can be mixed with charcoal shells while the process of burning (pyrolysis).

To choose the right supplier you have to be sure that this charcoal factory has its own coconut shell collection and pyrolysis process. If the charcoal factory buys coconut shells from other suppliers – quality can be different from batch to batch.

Having your own coconut charcoal collection and pyrolysis also will help you to solve the second biggest problem – long production time.

Coconut grows all year round in Indonesia, but sometimes it is difficult to find empty coconut shells at the right time. Sometimes farmers throw away coconut shells or burn them too much. That is why the price of coconut charcoal changes almost every week. Supply & demand also exist in this business.

If a charcoal factory cannot find enough coconut shells for the orders they can delay production or mix coconut shells with wood charcoal. That is why some batches of coconut charcoal can be different from others.

To be sure that you choose the right supplier of coconut charcoal you should visit a) a charcoal factory and b) coconut shells collection and pyrolysis facility. Usually, those places are located on different islands of Indonesia. Make sure that all those facilities belong to one owner. It will ensure a constant quality supply of coconut charcoal.

Another important notice on choosing a reliable supplier. Be sure that your supplier is a real factory and not a middleman. There are hundreds of so-called companies in Indonesia that claim that they own a charcoal factory. Do not believe them.

Check all company documents. For the Indonesian company, you have to check Akte pendirian, TDP, NIB, NPWP. Check whose name is on the documents, when they are expired, and what is the official location. Check if your sales manager’s name is written in those documents. Otherwise, you are dealing with a middleman.

Check the Bill of lading and other shipping documents. Real coconut charcoal suppliers can show you a pile of shipping documents, proving their existence. Cross-check B/L numbers with shipping lines (you can check it online).

Hire an independent surveyor to check the loading process, and the number of boxes with charcoal and make laboratory testing before shipping. You can use SGS or Intertek – they are pricey, but very professional and have a special SOP for charcoal testing.

Made a written agreement with the charcoal factory on the quality settlement. Professional charcoal suppliers are usually ready to sign that kind of contract. Write down what is the penalty for every change in the quality parameters of charcoal. For example, if ash is higher than 5% – the supplier has to pay you back 2% from the invoice. Or if moisture is higher than 10% – goods are subjected to a discount of 10%.

The safest way to protect you from unexpected quality change is to pay after you receive and check the goods. If you know the charcoal suppliers well – you can agree with them to pay after you check the coconut charcoal quality at the destination.

Step-by-step guide on how to choose a reliable and trusted manufacturer of shisha/hookah charcoal

There are many coconut shell charcoal briquettes factories who are manufacturing charcoal for shisha and hookah.

How to choose the right one, how to find a real factory, not just a trader? What to pay attention to while choosing a charcoal supplier. What to ask and what to check at the factory This and other questions will be answered in this article.

Trader or Factory

The first what you have to check is if you are dealing directly with a factory or just a trader.

Most of the traders claim that they are the factory, while they are just an intermediate. It is important to work directly with the factory if you want to get a good price and guaranteed quality.

Factories are less flexible in prices compared to traders. As traders can buy from different manufacturers and get lower prices by compromising the quality of charcoal. But on the other hand, you are sure that the quality is stable and the according to the contract.

Factory location

The second step is to know the real factory location. The size of the coconut charcoal factory is huge. Factories have to keep raw materials, production equipment, ovens, and packing materials.

The minimum size of the factory is from 700 m2 to 5000 m2. Always check if the factory really exists. To do it – just ask your manager to send photos & videos of the factory.

Ask to write your name and date on the piece of paper and put it on the equipment. So you are sure that this photo is not just from the Internet, but made especially for you.

Most of the coconut charcoal factories are located in Central Java, Indonesia. There are some factories in Kalimantan and Sulawesi. And just a couple of factories in the Jakarta area. There are no real coconut charcoal factories in Bali (as of 2022).

Why most of the charcoal factories are located in Central Java – the main reason is the level of salaries is less than in another part of Indonesia.

For example, in Jakarta workers will get twice bigger salary as in Central Java. That is why there are almost no factories in the Jakarta area.

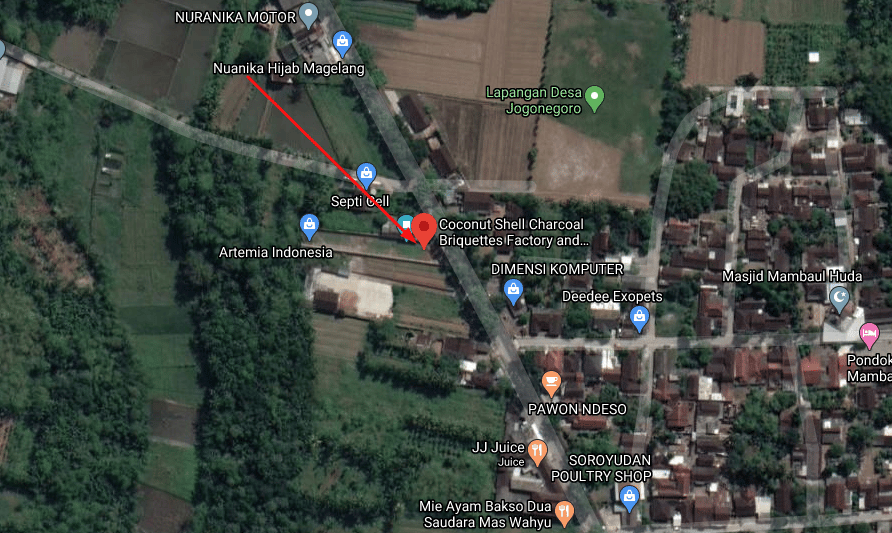

An example of the location of the coconut shell charcoal factory is by this link. (will open Google Maps in a new tab).

Is it Trusted Factory

After you find out that you are dealing directly with the charcoal factory and not a trader and your factory really exists – check if the charcoal factory is reliable and able to manufacture charcoal on a consistent basis.

So, how to check it: follow our step-by-step guide

Phone & website

Google the phone number and website of the factory. Do you see their phone number appear on other websites selling NOT coconut charcoal? If yes – it is very strange, do not believe this factory.

The phone number should be from Indonesia. The country code is +62. Be careful if the country code is different. Mobile phone numbers start with 8. So the mobile number will look like +628. Others numbers are home/office phones.

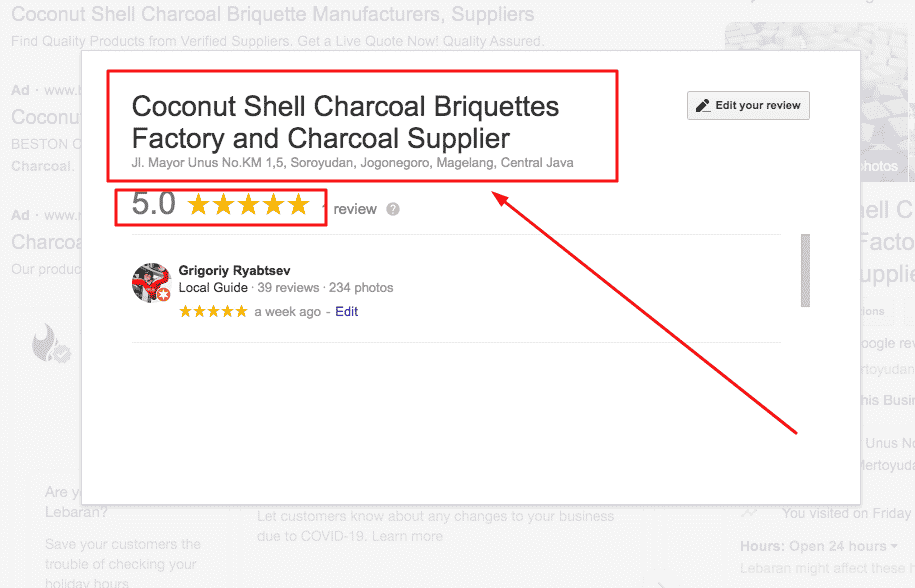

Reviews

A very simple, yet powerful method to check the factory is to find reviews. There are many platforms – that provide real and verified reviews from users. Check Google Review and Trust Review websites. If there is no review at all – very strange – do you work with a real factory?

But on the other hand, please remember that most probably people will write reviews if something bad happens, not when they are just happy with the service. So if there is a bad review – do not judge too highly.

Photos & videos

One of the most important parts is to understand the quality of the factory. Pay attention to the following:

- How clean is the factory? For sure it should not be too shiny or clean. As we are manufacturing charcoal – and charcoal nature is black and dusty.

- How workers are equipped – are they use masks or breath filters? Are they wearing corporate / branded uniforms with logos or the name of the factory?

- Can you see the stockpile of coconut shells? Zoom the image and try to read what is written on the charcoal packaging. Keep in mind that the factory should not keep any wood. As the best charcoal is made from 100% coconut shells only.

- How big is the factory? The average size of the charcoal factory is 1000 + sqm. So on video, you have to see approximately the same size.

Google street view

Open Google maps and write your factory name or address. Then switch to Google Street View – you will see the factory outside the gates. Check if the access road is enough to carry a big truck-trailer with 20″ or 40″ feet containers.

Factory equipment

One of the most important things to check – is factory equipment. If your factory has modern and automated machinery – you will get more stable products. So here are several parts that you have to check before ordering charcoal.

Charcoal ovens

Before sending it to you all charcoal briquettes have to be processed (dried) in ovens. It is a long and complicated process. Usually, it takes up to 36 hours of drying and 8 to 12 hours of cooling down.

Please check how many ovens the factory operates. What is the size of the oven? The good oven size is 3 by 3 meters. The bigger oven cannot dry charcoal consistently. And small ovens will take to a long time to process your order.

Check if ovens are equipped with industrial fans. How many fans do they use? Airflow circulation is a crucial part of the drying process. You do not want to get partially dried charcoal.

Charcoal cleaning

A coconut shell charcoal drum is used to clean coconut shells from dust and other particles. You have to check the length of the drum. The good size is 6 to 8 meters.

For Super Premium types – charcoal factories have to operate at least 12 meters cleaning shell drums. If you see a very short (less than 5 meters) drum – be careful – this factory cannot make good-quality charcoal

Charcoal grinding

The second step in the charcoal manufacturing process is grinding. Check with your supplier how many mesh sizes they have. It should be at least 2 mesh sizes for good quality charcoal.

Charcoal mixer

The charcoal mixer is a big vertical drum where charcoal is mixed with water and tapioca. The good size of the drum is between 100 and 300 kg.

If the drum is smaller than 100 kg – it will take too long to make your charcoal. If the drum is bigger than 300 kg – the quality of the charcoal would not be consistent.

Check the quality of the drum. See if there is any rust on the inner side of the drum. If you found rust – go away and never order from this factory.

Even a small amount of rust can destroy the quality of charcoal and make shisha smokers grimace.

Charcoal extruders

After the mixer – coconut shell charcoal entered to extruders hall. This is an area to condense and mix again the charcoal. The best charcoal factories – operate at least 3 extruders line.

Check if the extruders are equipped with cooling fans. As it is important to keep the charcoal temperature down, to prevent self-ignition and cracks.

Charcoal cutting

The cutting process affects the edges and accuracy of the charcoal cut. If you want to have sharp corners, and straight walls of charcoal cubes – check the cutting process.

Good manufacturing practice for coconut charcoal shells is to use still steel 0.5 mm circle knives. Space should be more than 1000 circles per hour. Less than that make cuts uneven and not sharp.

Charcoal trays for oven

After charcoal is cut – it is put on the trays. Best factories use metal trays. If your factory is “cutting corners” on prices – they will use wooden trays.

The most important to check the net on the tray. If it is straight and in good condition. If you find rust on it – be careful. No rust is allowed on any metal parts. As it will mix with charcoal and influence the taste.

Packing space

The packing space should be separate from the main production area. Charcoal production is very dusty. If the final product packing area is located too close to the production area – your boxes will be dirty and covered with black charcoal dust.

Packing areas need to be clean and with good air circulation to prevent your charcoal absorb smells.

Shell storage space

Coconut shells should be stored under the roof and protected from rain or water. The best way to keep charcoal shells is to put them on pallets under the roof.

Check if it is only charcoal and no wood available. Wood charcoal is not allowed to mix with coconut charcoal as it makes the one very low quality.

Charcoal laboratory

The heart of the factory. Check this place very carefully. All quality control is done here. First of all – a laboratory should exist at the factory. Not just a corner, but a separate room with equipment.

The coconut shell charcoal laboratory has to contain a moisture meter, weight scaleable to wight 1 mg – to measure the ash content. And the place for burning samples.

Charcoal samples storage

The accuracy of sample storage – is the symbol of accuracy at the factory. If you can see all charcoal samples stored with labels – it is good.

Samples storage should be huge. For each sample, the charcoal factory has to keep at least 50 kg of samples for future tests.

Office

Last but not least – office. It is located inside of the factory or outside. How many people are sitting there? Is it well organized or not?

How do they keep documents? Can they find documents fast and efficiently? Do they have document storage? Check all these items to make sure your factory is good.

Coconut charcoal Quality

After you check the factory and its equipment now is the time to check the quality of coconut shell charcoal by itself. The most important for shisha & hookah smokers are the following:

- charcoal is free from smell and taste

- charcoal is free from cracks and sparks

- charcoal ash is a very small and light color

- charcoal burns long and starts fast

So those were the most important specification that we have to keep.

Hand drawing

First of all, you can check the quality of charcoal by drawing with it in your hand. If the charcoal briquette left the black dots or lines – most likely your charcoal is mixed with wood and of low quality.

Sound test

This test helps you to understand the inner structure of charcoal. Just drop your charcoal briquettes (without flame) on the floor and carefully listen for the sound.

It should have a thin and ringing sound. No, a clunk sounds. If your charcoal sound is thin – it is proof that the briquette is hard enough.

More information can see on this video:

Drop test

The most commonly used test for charcoal. Burn your charcoal for 20 minutes, then drop it on the floor. Then count how many pcs of briquette are broken.

To make the right drop test you have to burn your charcoal first then drop it every 20 or 30 minutes.

See the video:

Burning time

Charcoal burning time is very important to enjoy good shisha. The average time (off shisha/standby) is from 1:20 to 2 hours. Just light up your charcoal and then put it to burn (do not forget to protect it from the wind and air blowing).

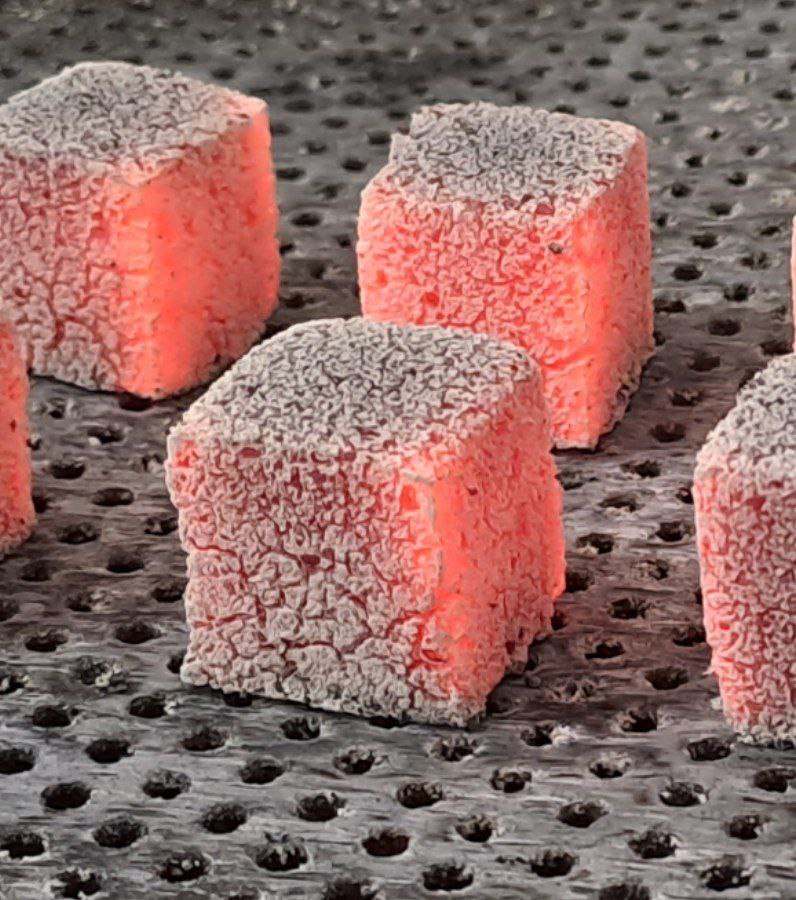

Glowing

Most of the buyers are not asking about flame glowing. While it is a very important and crucial part of charcoal. Glowing should be orange to red in color and consistent during the all burning

No black spots or black areas are allowed in good charcoal. If your charcoal gets black spots – do not buy it, it is mixed with wood or dust.

Ash color

The Ash color of coconut charcoal is usually grey to white. Some factories claim that they make super white natural charcoal – do not believe them. All super white charcoal uses chemicals to make its color bright.

The best is grey to white color without black or brown dots. Check the ash color for brown or green shades. It should be all in one tone.

Ash content

Ash content is the main point to choose good quality charcoal. Less ash is better. The average Super-premium quality ash content is between 1.5 to 2%.

Good charcoal contains from 2 to 2.5 % of ash. All that is above is just average or less-than-average quality charcoal.

Be careful to measure charcoal ash content with the right moisture. Otherwise, you will get very different results every time.

Moisture tricks

Some factories intentionally increase moisture content, to reduce the ash value. The right moisture should be between 6 to 8 %. No more, no less. It is ideal for good and long burning.

If you have higher moisture – your test will show less ash content, while the actual ash can be very high. Ask your factory about moisture and testing methods.

Coconut Charcoal briquettes Pricing

The other way to check the quality is to compare prices for charcoal. If your price is very low – please think twice. As the production cost for charcoal is high, the factory margin is low. So good quality charcoal cannot be sold at a price of less than 900 USD per ton.

Conclusion

Before you buy coconut shell charcoal – please check all steps to be sure of the quality of your supplier and the quality of the product. Manufacturing charcoal is not an easy process (even if it seems very basic). There are a lot of hidden “stones” that can break your charcoal.

Please choose the right supplier and make sure your clients can enjoy shisha all day long.

Instruction on how to know if you are dealing directly with factories or with intermediates like brokers or agents.

There are dozens of coconut shell charcoal factories in Indonesia. Almost all of them are selling both directly and via intermediates like brokers, agents, or traders. From this article, you will know how to check if you are dealing directly with the factory or not.

What is the difference between buying directly from a factory or from a trader?

It is always better to deal directly with the factory without any intermediates. First of all, the agent adds their margin to the price. The average agent/broker bonus is from 20 to 50 USD per ton.

So, if you are buying coconut shell charcoal for shisha or hookah with the price of 1200 USD per tone – the actual money factory gets it just 1150 – 1170 USD per tone.

Less price of coconut shell charcoal – less quality you get. For sure, the factory protects their agents/brokers and does not disclose that you are dealing via an intermediate.

If you want to keep the charcoal quality good and have the best price – it is better to deal directly with the factory.

Pro’s & contra buying directly or via an agent

Pro’s

Buying via a broker has its own advantages. Most brokers work with several factories. That is why they can keep the price and volume at a good level.

If one factory having problems with raw materials – a broker can fast move your order to another factory and keep the timing according to the plan.

Agents, brokers, and other intermediates are good at marketing and sales. It is much easy to communicate with them. They speak good English and are able to explain specifications and pricing. On the other hand, sales managers from factories are usually less client-oriented.

Contra

First of all, is the pricing. As I wrote at the begging of the article – brokers add their margin to the price. So you have to pay 30 or 50 dollars per ton more.

Actually, you are not paying more, but get 30 or 50 USD less quality than expected. The factory will decrease quality in order to keep the price level the same and be able to pay a broker his fee.

Brokers are not responsible for the quality, quantity, production time, and all other issues. If you get problems with your charcoal – the most likely broker will forward your problem to the factory.

If there is a problem with the factory – a broker can do nothing to help you. So, basically, you are paying a broker without any insurance or guarantee that your problem would be resolved.

Photo of factory

The first and most easy part is to ask your seller to give you a photo of the factory. Just a general photo of the production area and gate entrance.

Pay your attention to the gate entrance – usually, real factories write the name of the factory next to the gate or entrance. Be sure that the name on the factory entrance is matching your seller company name and website.

Then you may ask your seller to take a photo with paper where he writes your own name. By this, you can confirm that photos are up to date and not just general photos.

Please note how long it takes for the seller to make this individual photo. If you ask to make a photo today, but the seller sends it the next day – it is strange.

For sure, do not forget the time zone. Indonesia is in GMT +7 hours. So when it is day in the USA, in Indonesia is already night.

Video from factory

The same you can do with the video. Ask your seller to provide a video of the factory and main entrance gate. Count how long it will take to make a video.

Ask the seller to name you in the video, so you can clearly hear your own name in the video. It will prove that this video is made only for you.

If you are dealing directly with the factory – the seller can make the video very fast, as he/she is sitting at the factory. But if your seller is just an intermediate – it will be much longer.

Besides, it asks the seller not only to say his name but also to introduce himself in the video. It is important to do to eliminate the situation when a broker asks someone at the factory to shoot a video on their behalf of him.

Check the GPS coordinate from the photo

Easy and powerful hack – to check the photo meta tags. Each photo was done by smartphone and usually contains GPS data coordinates. So you can open this photo on your computer, then right-click on the photo and choose “Properties”, then check the “Tag” section. There you can find two long numbers.

Just copy-paste those GPS coordinates to Google Maps and click “Search”. Google will point to the location where the actual photo was taken. Zoom in, switch to the “Street View” and see if the factory data is the same as information from Seller.

Check if the photo & video are consistent

While the Seller is sending you photos & videos, pay attention if those photos were made in the same factory or not. Look at the walls, floor, lighting, and other specific things. Most of the coconut shell charcoal briquettes factories own only one location.

So, if you Seller gives you different locations – most likely he is not the factory, but a broker.

Surprise video call

This is one of the best ways to check the truth. Calculate the time in Indonesia (GMT +7). Then choose the working hour. In Indonesia, most of the charcoal factories work from 8 am to 5 pm.

And make a video call (use Whatsapp) at, let’s say, 11 am. For sure at this time your Seller should be at the factory. As soon as he picks up the phone pay all your attention to the surrounding. Is it an office or factory location?

Ask him to go outside and show the actual factory. This “surprise” works very well.

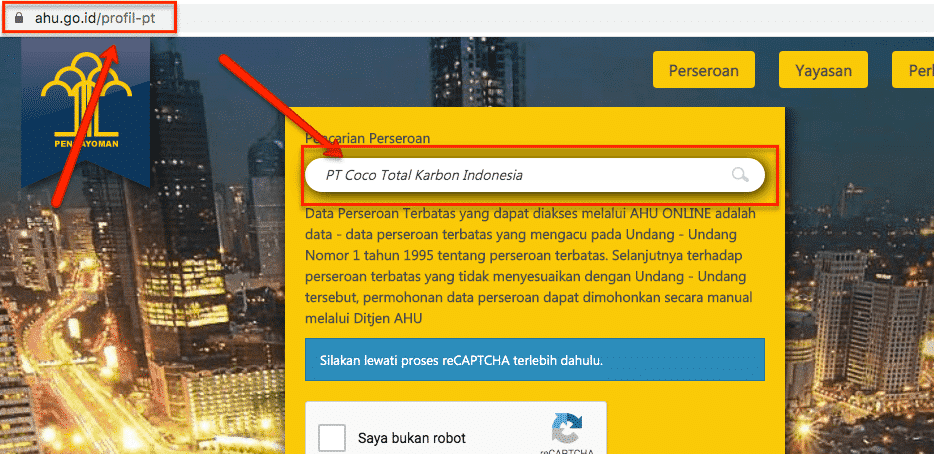

Check the legal name of the company in Indonesia

Ask your Seller to provide the real factory’s legal name. In Indonesia, all legal names should start with PT. (equal to LLC) or, less likely, a CV.

It is impossible for Indonesian companies to have in their name “western” LLC, Ltd, or another extension. Usually Indonesian legal name consists of 3 or more words, starting with PT.

For example, our coconut charcoal factory’s legal name is PT. Coco Total Karbon Indonesia.

After you get the legal company name – go to the Indonesian Government company repository website to check if the name is legal. Click the link https://ahu.go.id/profil-pt (will open in a new window).

Do not be afraid, it is very easy and free to check the Indonesian company’s legal name. Just input the company name in the field, click Captcha and wait.

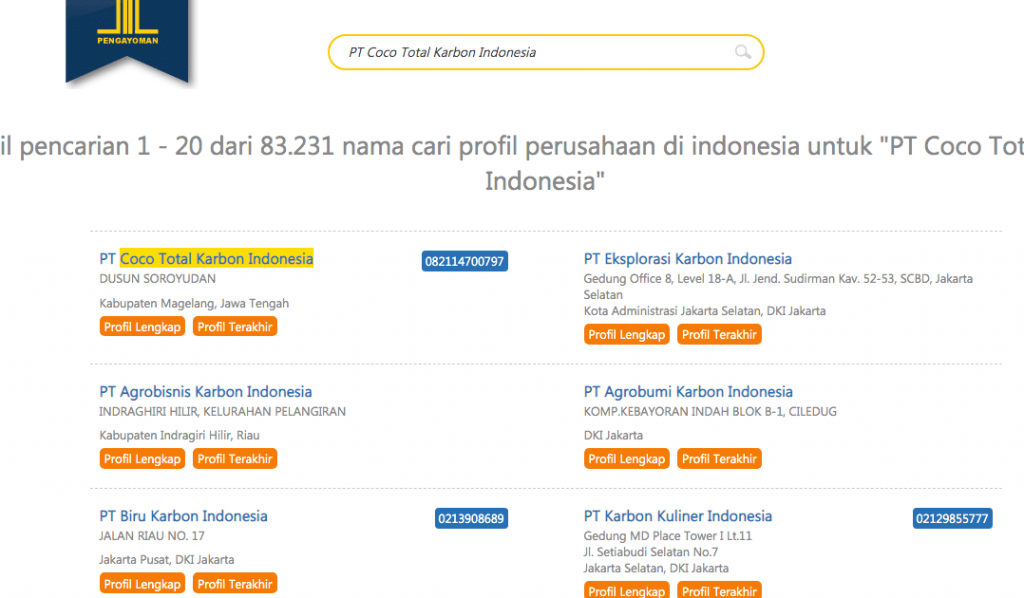

This is the official list of all Indonesian companies. There is no way the factory can work without being legally registered. So the result of the search should be similar to this picture:

You can see that our charcoal factory name (PT Coco total Karbon Indonesia) is a legally registered company. It means that we exist.

From this search, you can see the legal address (it should match with the factory location and phone number of the person in charge of this factory).

If your Seller company is not fully matched with the result or does not exist in this search – it means that you are dealing with non-existed, not registered factories.

Googling the reviews of the company

Another simple way to check your seller is to Google the review of the factory. Simply write the factory name in the search and see the results.

You can find how many websites it is registered on. Then add the word “review”, and “fraud” to the company name. By this, you can find all information published on the Internet about your company.

Googling the phone number & email

As you’re communicating with the Seller, just try to Google his phone number and email. Very often you can find interesting information.

If your Seller’s phone or email is listed on another website, not related to this charcoal factory – it means you get a broker, not a factory.

Social media check

Ask for your seller’s full name and search it on Facebook, LinkedIn, and Instagram. Read the wall and see the photos. You will understand more about your Seller.

Check how many posts & photos are related to charcoal production. How many photos are related to the factory? All you can find on social media

Visit Indonesian Export Center

This is the most time-consuming but working way to check the truth. Go to the Indonesian Embassy in your area and ask for the Export Center representative.

Those representatives work closely with all exporting companies and know who is working and who is fake. It takes time and is subject to many factors, but it is still good to check, if possible.

Payment terms and account

This is a fast method to check your Seller factory. Ask your seller to issue a draft of the proforma invoice. And then check what the company name is written on it. Is it matching your Seller information?

Then check the bank account number. Pay attention to the account name owner. It should be the same as the legal company name. Do not transfer to private or personal bank accounts.

Conclusion

To check if you are dealing directly with a charcoal factory or with a broker is easy. Most methods require only a computer and the Internet. You can do it in just a couple of minutes.

So be careful and buy charcoal only from the factories in order to keep quality high, and price low.

How to check the quality of coconut charcoal briquettes

Very easy technique on how to check the quality of coconut briquettes.

Take your briquettes and drop them (without any power) on the floor from the one-meter height.

Listen to the sound. Lighter and sharper sound is – the better quality of charcoal.

If you want to buy bulk wholesale coconut charcoal briquettes from the factory – WhatsApp or email us: +62 85328727291 export@charcoal.pro https://charcoal.pro

5 Myths About Coconut Charcoal for Hookah

This article is written for one who is buying coconut charcoal for wholesale or export/import purposes. If you are just smoking hookah/shisha – do not read this article.

I am a manufacturer of coconut charcoal for hookah and shisha. My charcoal factory is located in Magelang, Central Java, Indonesia. Every day I receive 2-5 inquiries for coconut charcoal. I find out the 3 most common myths about coconut charcoal.

Coconut charcoal myth #1. Buying coconut charcoal from Indonesia is very cheap. Well, yes it is particularly true. Coconut charcoal in Indonesia is cheap but not very cheap. The price for coconut charcoal for hookah in Indonesia was between 1,000 and 1,450 USD per ton in January-April 2019. This price range is due to a different specification. So better quality – higher the price.

Please do not believe that you can buy coconut charcoal at a price of $500 to $900. Sure you can find a couple of proposals on Alibaba to buy this super cheap coconut charcoal. Most of these proposals are fake. Or they sell you not a coconut but wood charcoal.

Why you cannot buy coconut charcoal for cheaper than 1000 USD in 2019? The price of coconut charcoal depends on the price of coconut shells. Coconut shells cost from 300 to 500 USD per tonne if you buy directly from farmers without a middleman. After buying empty coconut shells you have to clean them from the residue, coconut meat, and coconut hair. Then dry it under the sun for a week.

Only after that, you can start burning and making coconut shell charcoal. To produce 1 kg of coconut shell charcoal you have to burn out 5 kg of empty sun-dried coconut shells. Then you have to bring it to your factory to crush and mix it with formula.

The final production cost of coconut charcoal for hookah and shisha is about 900 to 1300 USD per tonne. The charcoal factory makes from 10 to 15% profit. So do not believe someone sells you coconut charcoal at a price cheaper than that.

Price can change due to Rupiah to Dollar exchange rate. Charcoal factories are buying coconut shells paying in Indonesian Rupiah (IDR). If USD is high – and Rupiah is weak it means you can buy more charcoal with the same amount of USD.

This happened in November 2018, when the price IDR to USD was 14500, and buyers purchased good coconut charcoal at the cost of 800-900 USD per tonne.

Coconut charcoal myth #2. Buying coconut charcoal for hookah and shisha is easy in Indonesia. Yes, there are about 30 charcoal factories working in Indonesia. But you can find several hundreds of middle man you pretend to be or to own charcoal factories.

If you are lucky and find a coconut charcoal factory (like mine) – please be ready to wait in line to get your orders. Why? For example, my charcoal factory can produce up to 1 container of coconut charcoal a week. I have 5 regular buyers who order once every 2-3 months. Often two buyers order at the same time. So it means one has to wait while I produce for another.

Another problem is the availability of empty coconut shells. Two-three times a year becomes very difficult to find good empty coconut shells for production. So some charcoal factories start to mix coconut with wood charcoal.

Coconut charcoal myth #3. It is easy to maintain the constant quality of coconut charcoal. Unfortunately, it is far from the truth. Specification of coconut charcoal depends on a) the quality of coconut shells and b) the mixing formula.

The quality of coconut shells is the most important part of manufacturing coconut charcoal for hookah & shisha. The burning process (pyrolysis) influences the ash content and ash color. If the burning of coconut charcoal was done wrong or the shell was mixed with wood ash, earth, or clay – do not expect high specs.

Each batch of coconut charcoal shells can be different in terms of specification. The biggest headache at the charcoal factory is to separating good charcoal from low specs charcoal.

Mixing formula – is the biggest secret of all charcoal factories. How much of tapioca, other chemicals, and wood are added to the coconut charcoal? How to make coconut ash become whiter and drop test show higher results? It all depends on the mixing formula.

You should be ready that the production of coconut charcoal can be different from batch to batch.

10 steps to check if you are dealing with real coconut charcoal briquettes factory

If you are looking for a coconut charcoal supplier in Indonesia – you can find hundreds of websites claiming that they are the real manufacturers. On Alibaba dozens of ads proposing you coconut charcoal for hookah & shisha at various prices. How to find out if is it a real factory, a real supplier or middleman, or even a fake?

You should know that there are about 30 working factories of coconut charcoal in Indonesia. Most of the factories are located in Central Java and Sulawesi. Most of the coconut shells are from North Sulawesi. There are several factories in Kalimantan and Sumatra.

Check how to check Indonesian coconut shell suppliers:

- Check if the coconut charcoal factory is a legal entity. Most of the companies in Indonesia have PT or CVs before the name. Go to the website of the General Director of Law https://ahu.go.id/profil-pt and write down the name of the company without PT or CV. If you can find the name of the company on the list – it is a legal and registered company. If there is no exact name in the list – it is a fake factory.

- Compare the prices. Send price requests for coconut charcoal to several suppliers. Compare the prices. If there some prices are 30-50% cheaper than average – it may be a signal that they are fake producers. Most charcoal factories have the same price due to the similarity of the production process and the cost of acquiring coconut shells.

- Make a video call. Use Skype or Whatsapp to make a video call to your sales manager. Call during working hours in Indonesia (GMT +7). See if the sales manager is in the office or in the charcoal factory. If the sales are at home – ask when you can call him to see the real factory. Ask the manager to go around the factory or office to show that it is a real charcoal factory.

- Ask the seller to send you photos of stock, and loaded containers. Ask him to write down your name or today’s date on a piece of paper and put it on the stock of charcoal. It will help you to prove that the photo is made special for you and not just a photo from the Internet.

- Check the information on the Bill of lading. Ask your seller to send you a Bill of lading already shipping containers with coconut charcoal. Check who is the shipper/sender, is it the same name as the factory? What is the description of the goods? Check the date of the issue. How many months or years ago this document was issued?

- Ask to send you samples of charcoal. Usually, samples are free, but delivery is paid for by the receiver (you). Pay attention to how fast the seller prepares samples. Usually, real factories send samples the next day.

- Ask for references from previous buyers. It is ok to ask for the phone number of their buyer. Call them asking did they really buy from this charcoal factory. It is a simple but powerful tip to check the charcoal factory. If the seller cannot provide you with customer information – be careful.

- Visit the coconut charcoal factory. Arrange your visit to Indonesia to see the coconut charcoal factory with your own eyes. It is easy to visit Indonesia, probably you do not need a visa to come here. Check it before coming. 2-3 days is enough to visit 5-6 charcoal factories in Indonesia. Ask the seller to pick you up at the airport and bring you to the factory. After arriving at the factory you can talk to workers, ask them who is the boss. Do not ask them very complicated questions, just say in Indonesian – “Siapa bos di sini” – who is the boss here – they will show you the real owner or manager.

- Google the company name – see the comments. Try to write the company name + work “fake” on Google. If there are any negative comments – be careful.

- Go to Google Maps and open the coconut charcoal factory address. Switch to the street view. See if the building looks like a factory, is there any sign of the charcoal factory? You should do this step before coming to Indonesia.

It was 10 main tips on how to check the coconut charcoal factory in Indonesia. Most of the factories are real and working well. Just be careful and use common sense to check the charcoal supplier.

Easy to use the tutorial on how to check the quality of your coconut charcoal.

How to check if your coconut charcoal briquettes contain wood

Take any of your briquettes and scratch them onto your bare hand. If there are tracks of charcoal – it means you get wood in briquettes.

Reminder – good quality coconut charcoal briquettes contain only coconut charcoal shells and no wood.

If you want to buy bulk wholesale coconut charcoal briquettes from the factory – WhatsApp or email us: +62 85328727291 export@charcoal.pro https://charcoal.pro