Table of Contents

The ultimate guide to wholesale hookah coal & shisha charcoal packaging

Greg Ryabtsev, the coconut charcoal expert, writes this article. Initially, the first version of this article was very short, written back in 2017 and then updated several times.

In this late version, the article was entirely rewritten by Greg in 2023 and also added new items in 2025, adding many more photos, box specifications, new versions of charcoal packaging, and some prices, too.

This article is dedicated to wholesale buyers of shisha charcoal, also called hookah coals. I assume you are already buying shisha charcoal or planning to buy the bulk of hookah coals from us or another charcoal factory.

This article will discuss what types of packaging are used for wholesale coconut charcoal briquettes, i.e., hookah coals. You will understand the differences between packaging and differences in prices, too.

The result of the article: you will be able to decide what type of packaging best fits your needs, and understand the pros and cons of different packaging.

If you have any questions or suggestions, please feel free to contact Greg Ryabtsev by WhatsApp at +628118797070 or email export@charcoal.pro

Why hookah coal packaging is important

First of all, the packaging is the first thing seen by your end customer and the first thing that protects your charcoal from damage.

Damage protection

Even though coconut shell charcoal briquettes are relatively strong and seldom break apart, it still need protection from physical damage. During loading and unloading, handling at the warehouse, and transportation, charcoal boxes can fall and get some physical cracks.

Another essential feature is to protect shisha charcoal from water or moisture. We want to keep our charcoal easy to heat up and burn at high temperatures, but if charcoal is exposed to water, it can damage charcoal’s main function: burn and give high heat.

Moreover, do not forget that manufacturing shisha charcoal is very dusty. Yes, a lot of dust is produced during manufacturing, and a lot of this dust will end up in your charcoal. Do you want your clients to take charcoal with bare hands and discover that their fingers become black because of charcoal dust? Sure, no, that is why it is important to ensure proper packaging to protect from dust from goods.

Another essential packaging feature is keeping charcoal from exceeding heat during transportation and storage. Our coconut shell charcoal briquettes are safe from self-ignition, which an independent laboratory with an SHT test proves. But anyway, playing safe and keeping charcoal from exposure to direct sunlight is a good idea. The excellent packaging will help with it too.

Good look

Yes, the packaging is the first thing that your customer sees. It is your first impression of your charcoal end user. It should be nice to talk about hookah coal quality. Good packaging helps you not only to make an excellent first impression but also to sell charcoal fast. It helps to stand out on the shop shelf, attract more attention, and promote itself just by how it looks.

Nice packaging also helps to distinguish your charcoal from other brands and stand out from a crowd of other shisha coals.

One more thing is with good packaging, you will easy to count and keep an eye on your product stock.

Hookah Coals packaging

The standard coconut charcoal briquette packaging for shisha/hookah consists of inner plastic, inner box, and master box. I will explain what it is and how to choose the best for you.

Inner plastic

Inner plastic is a PE type of plastic. It is mainly and widely used for inner packaging. It is the last level of “defenses” for your charcoal.

By request, eco-friendly, fast degradable plastics from organic sources can be available.

The primary function is to protect shisha charcoal from moisture, moisture, and dust. It also keeps the shape of charcoal as it is supposed to be.

Inner plastic is available in various sizes; the most popular is 1 kg packaging. But also available in 250 gr, 500 gr, 125 gr, and 60 gr packaging.

Manual duct tape and machine sealing

In general, the inner plastic is plane, semi-transparent plastic. It is sealed manually with transparent duck tape or an automatic sealing machine. It is applied on the upper lid of the inner plastic.

Duck tape can be also branded with your own brand printined along the duck tape

Not many brands use branded duck tape, and the minimum order is 50+ tons of charcoal to print duck tape.

What is better to use: manual duct tape or a sealing machine?

The most popular way is to use manual duct tape, the most common way to seal the inner plastic.

Automatic sealing is faster. It also makes your inner plastic vacuum packed, but on the other hand, it adds several dollars to the ton as an additional cost. Moreover, with automatic sealing, you cannot use stickers for your boxes.

But with automatic sealing, a big space occurs on the plastic’s upper part. So, the charcoal packed is not as tight as with manual duct tape sealing.

Plastic Screen Printing

Plastic is not only suitable for the protection of your charcoal, but it is also suitable for your branding. We can print color brands on the inner plastic.

Printing is counting based on several colors. Most of the clients are using one or two colors of screen printing. But we are not limited and can use up to 15 colors on the same plastic.

Please keep in mind that printing on plastic will take additional time, usually is is 2-3 weeks again. So it is essential to reserve enough time before ordering this type of packaging.

Moisture absorber

In each inner plastic, our factory adds silica gel, a food-grade moisture absorber that helps keep your charcoal dry.

This symbolizes extra care for your clients, showing them that all small things matter. It is very important to have this moisture absorber in each bag as it helps to keep charcoal dry.

Since 2025 we are able to make customized silica gel for your packaging.

We can add your logo to the moisture absorber.

It looks very cool, especially if you add your logo on it.

On other hand there is a minim order volume of 200 tons of charcoal (200000 pcs of silica gel) to make it.

For sure you do not need to buy it in once, but you can pay and store it at our factory.

Production time for custommized silica gel with your brand is 2 monthes.

Stickers

Stickers are round or sometimes square stickers glued to the inner plastic’s upper lid. It is visible only when the customer opens the master or inner box. It is an additional branding element and shows your buyers how you care about them.

We can add vinyl stickers on the inner plastic. When you open the inner box, your customer will see the sticker with your brand name instead of just plain inner plastic.

The sticker not only looks good, but it also works as an additional multi-use seal for the inner plastic.

After your clients open the charcoal, they can properly close it with the striker again and keep it protected from moisture.

Stickers can be round, square, or oval in shape.

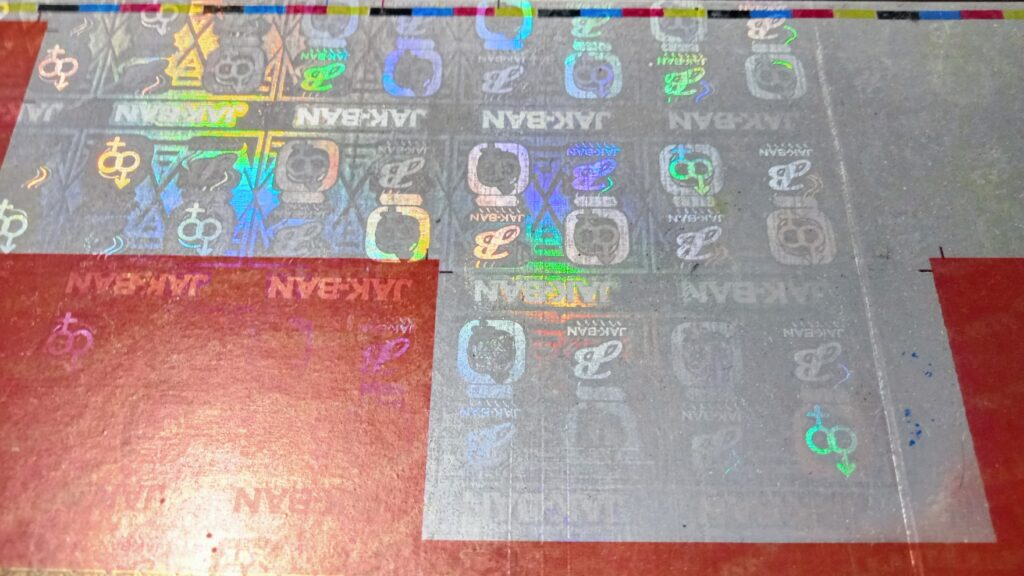

Hologram Stickers

In the world of shisha charcoal, hologram stickers are like your packaging’s bodyguards, keeping copycats at bay and adding that extra wow factor.

These silver marvels, when tilted just right, reveal your brand’s logo or symbols, making your packaging pop with personality.

I have written an additional article about hologram stickers for shisha charcoal, please read it too.

Inner plastic production time

Usually, we have an extensive stock of inner plastic at the factory, so there is no time needed to reorder it. But again, if you want to print on plastic, your brand or order is not a standard size (not 1 kg 500 gr, or 250 gr), it will take additional time, approximately 1-2 weeks for the production and delivery to our factory.

Inner Box

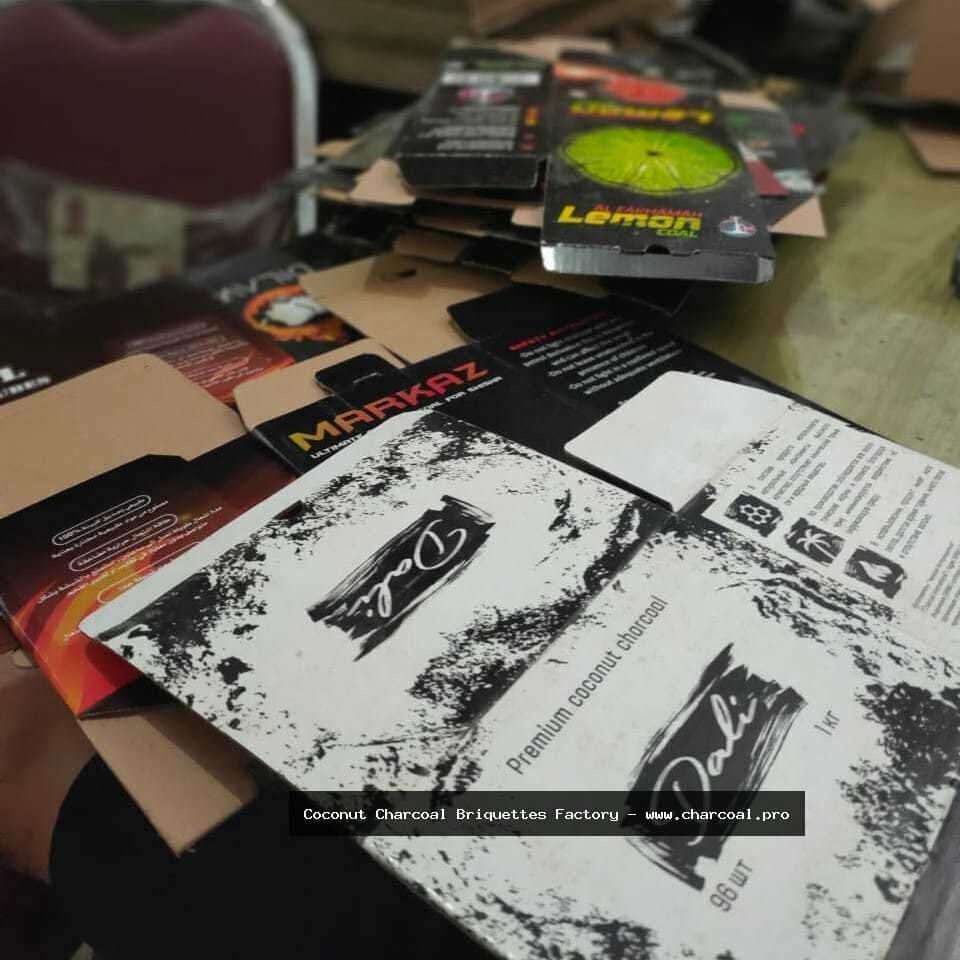

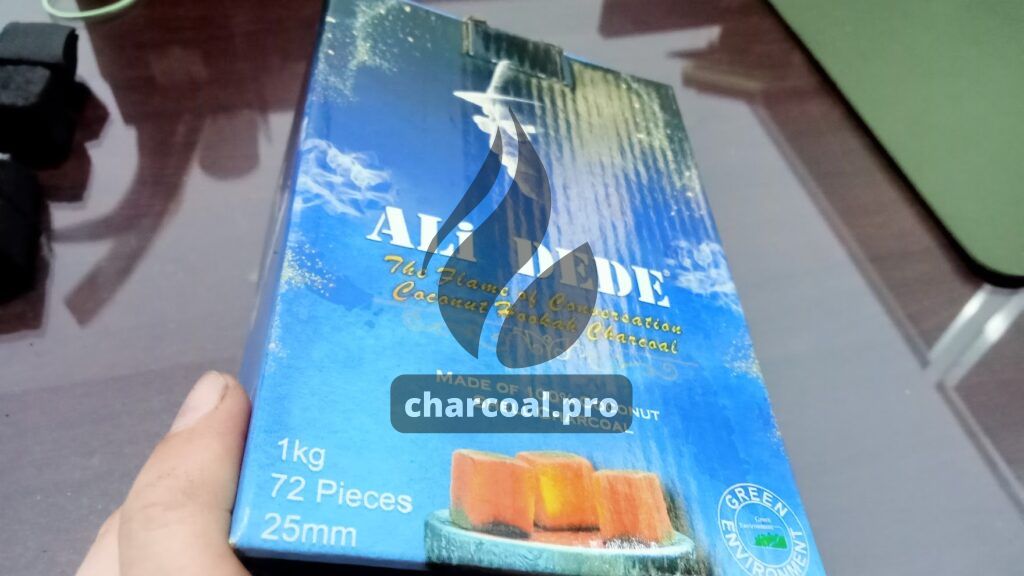

The inner box is a carton box printed with the client’s brand. It is the main box that is being displayed in shops. All design ideas should be focused on the inner box. As I wrote before, the inner box makes the “first impression”, so please be sure you make the best first impression by applying good design and good quality paper.

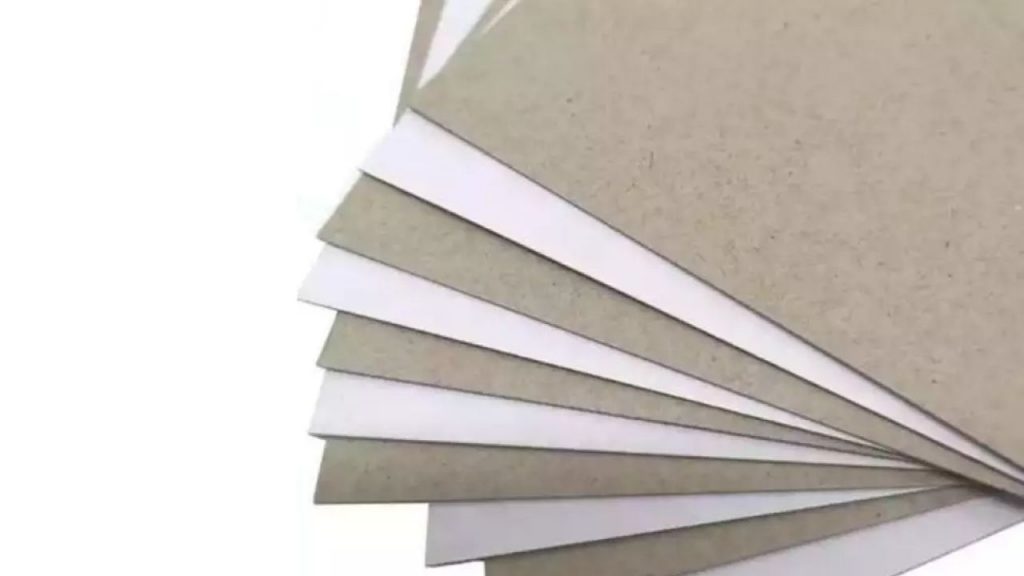

The inner box is made from corrugated e-flute and covered with duplex paper.

E flute

An E flute box is a corrugated cardboard packaging designed to provide strength, durability, and protection to various goods during shipping and storage.

It is named after the flute type used in its construction, where the term “E flute” refers to the thickness and size of the corrugated material.

Compared to traditional cardboard boxes, E flute boxes have a thinner profile due to their more minor flutes, which are the wavy, arch-like shapes between the two flat linerboard layers.

The E flute is generally about half the thickness of a standard corrugated box’s flute, such as the B or C flute. This makes E flute boxes ideal for packaging hookah coals.

Duplex paper

Duplex paper, a popular choice for the cover material in E flute boxes, consists of two layers with different properties. This versatile paper is well-suited for various packaging applications, including E-flute boxes.

Duplex paper quality

Duplex paper is the upper layer of the inner box. All colors and prints are applied to the duplex paper, not to the e-flute corrugated carton.

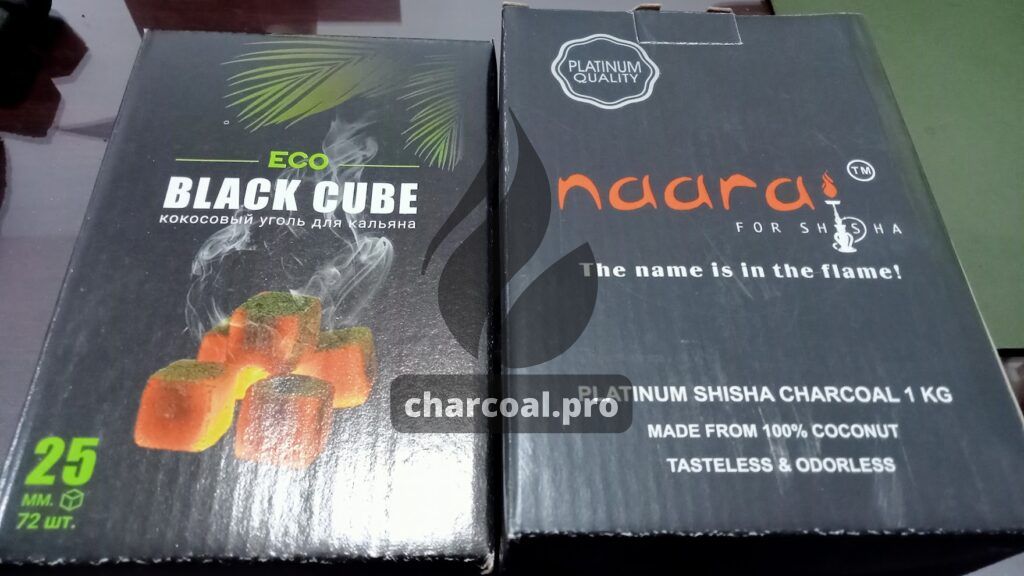

The thickness of the duplex paper is very important to make your box stand out from others. The standard thickness of the duplex paper is 250 gr.

With the standard thickness of a duplex, you will see the ‘ribs” on the box surface. Those ribs are from corrugated e-flute cartons.

If you do not want to have those ribs on your packaging and want your hookah coal box to look much more exclusive and luxurious, the best is to use thicker duplex paper. Instead of 250gsm, we recommend using 270, 310 gsm, or 350gsm.

For comparison, see the photo below:

inner-box-for-shisha-charcoal-standard-packaging-vis-good.jpg

It is visible that the box on the right looks better than the left one. The difference is in the thickness of the duplex paper.

Again, with thicker paper comes a higher price. In general, thicker 310 or 350gsm duplex paper costs an additional +80 USD per ton. Quite a price for the nice look.

How to make it cheaper? Simply order 100k+ boxes at once, and the price will be much lower.

Inner box layout

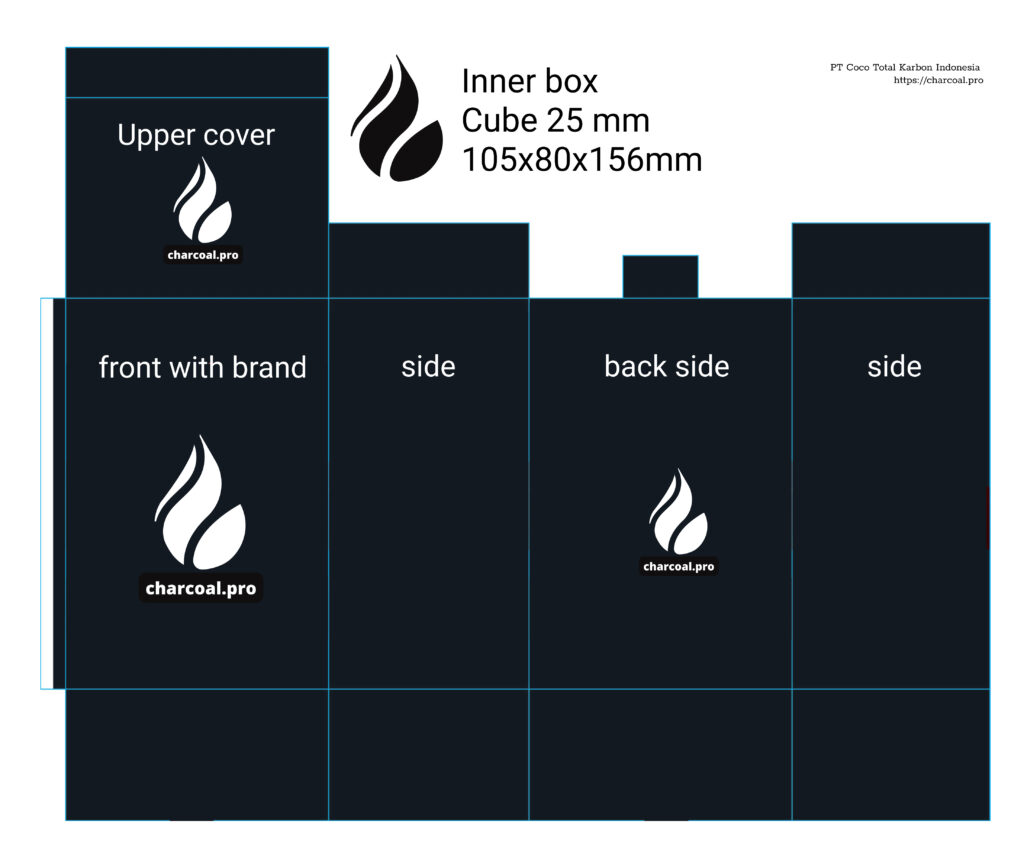

Below is the layout for the most popular box size: for coconut charcoal briquettes, shape cube 25 mm. You can use this layout to give to your designer to fit your design to the actual box size.

The buyer usually does the design & layout of the inner box. We manufacture under clients’ brands only.

How does the size of the inner box vary based on the size of the charcoal cubes?

The dimensions of the inner box for coconut charcoal can differ depending on the individual size of the charcoal cubes. On average, a standard inner box typically measures around 108 x 98 x 150 mm. However, these measurements can fluctuate to accommodate various cube sizes, ensuring an optimal fit and efficient packaging.

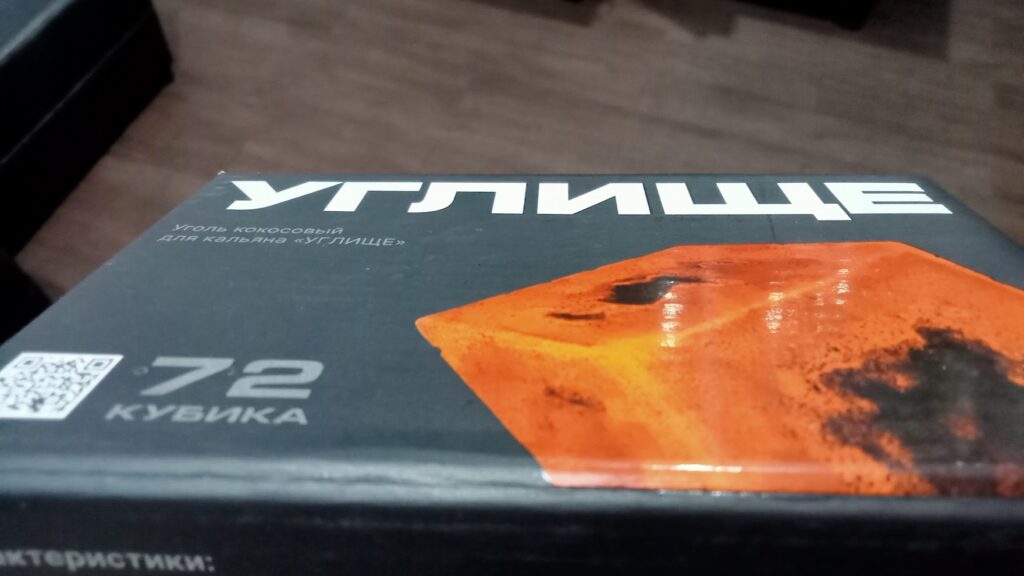

Cube 25 mm 1 kg

The most popular size is for a 1 kg cube 25 mm.

The box size is 105 x 80 x 57 mm with upper lead closing. Approximately 90% of all 25-cube charcoal cubes are packed inside this box.

Inside one box are 72 pcs: 6 layers of charcoal with 12 pcs of cube 25 mm in each layer. With a three-by-four layout.

The total weight is 1 kg and 25-35 gr of charcoal plus the weight of the inner box.

We can request the exact size and layout of the box. Please WhatsApp us +628118797070

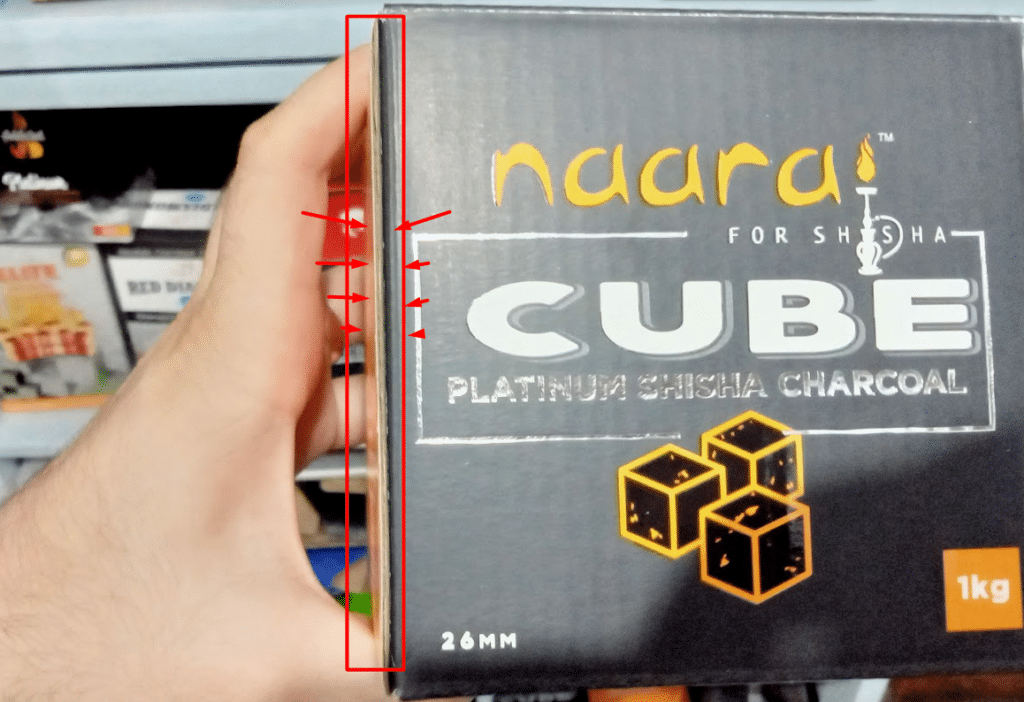

Cube 26 mm 1 kg

The second most popular size of shisha charcoal is a cube 26 mm. It is 64 cubes per 1 kg with a four-by-four layout of cubes. With a total of 4 layers of cubes.

The common size for the inner box is 111 by 111 by 111 mm.

If you need an exact layout for your designer, please get in touch with me by WhatsApp or Email.

There are a lot of other sizes and box types available. For example, very popular in Russia and Europe is packaging by 250 gr. For a cube 25 mm, it is 16 pcs per box.

The box size is 80 x 55 x 80 mm. Usually, the small box is made just from Duplex 310 or 450 gsm, with UV finishing. The box size is small but still very popular among home users.

Another very popular design of the box is one with a separate upper lid. This type of box is 3 to 5% more expensive in printing as it has a separate upper lid but is easy to use.

The standard size for this type of box is 110x111x111 mm. The main box body is made with duplex paper and E Flute, while the upper lid is covered with duplex-only paper.

The most popular shape is a standing vertical box, but in my opinion, the best for clients is a horizontal box. Somehow only a few brands implement this user-friendly box design

Why horizontal is better: It is opened on a wide side, and it is much easier to take charcoal with bare hands. The cost of production for both types of box shapes is the same.

Other box shapes & sizes

If you are planning to order cubes 20, 22, 26, or 27, and 28, 29, 30, and 31 mm or stix/finger shape the box layout will be different. Please contact me by WhatsApp or Email to get the proper box layout and size.

3D visualization of the inner box for Cube 26 mm

3D visualisation of inner box for Cube 25 mm

Besides it, we can make more unique shapes to fit your needs.

Open top, side opened, and many others.

Pro Tips #1:

Do not forget that there is a difference between where glue is located on the box. So the box is cut from the list of paper and then folded together. The location where one side is attached and glued to another is called the “glued side” of the box.

So the glued side of the box can be in front: where the upper lid lock is located or at the back. The most popular and recommended location of the glued side is the back side of the box. See the image below.

But, again, you can choose by yourself where to put the glued part. It is really pro tip that 99% of charcoal buyers even do not know about it.

Pro tips #2

The location of the lock of the upper lid. Actually, there are two variants for upper lid location: on the top of the lid or on the side of the box.

The most popular and common location of the lock is the side wall. Again, while printing you can choose the location of the lock by yourself.

What is the importance of laminating and double-color printing for the inner box?

Laminating and double color printing for the inner box are crucial for achieving a polished and durable finish. When printing solid or “block” colors, such as all black or grey, these methods ensure a sharper, more vibrant appearance.

Why Laminating Matters

Laminating adds a protective layer to the printed surface, which:

- Enhances durability: Prevents scratches and wear, keeping the box looking pristine.

- Improves aesthetics: Provides a glossy or matte finish that elevates the overall look.

The Role of Double Color Printing

Double color printing involves printing the background color twice. This technique:

- Intensifies color: Ensures a deep, uniform hue, particularly for dark shades.

- Prevents visual imperfections: Reduces streaks and uneven patches, creating a smoother finish.

Additional Costs

Bear in mind, lamination incurs an extra charge of $25-$30 per ton. However, this investment is worthwhile for the enhanced quality and longevity it provides to your packaging.

Inner box plastic wrapping

By request, we can wrap your inner box hookah coals packaging inside the plastic. It is shrinkable PVC plastic that adds an additional layer of protection to your boxes. It keeps it from moisture and dust.

But again with additional wrapping comes an additional cost of approx 22 USD per ton.

Outer wrapping can by done by automatically by heat wrapping machine or manually.

Inner box finishing

Finishing the inner box means what the outer cover of the color is on the box. The standard one is UV finishing.

Besides UV finishing, we can do:

- water based finishing (the cheapest one)

- UV finishing (standard) Matt or Glossy

- OPP finishing Matt or Glossy

What is the difference between UV-based finishing and Water based finishing?

Basically, it is the quality of the “skin” of the box. UV makes it shinier and more protected compared with water-based finishing. UV-based finishing and water-based finishing are two different types of surface coatings used for hookah coals packaging.

Standard (at our factory) is UV-based finishing. But keep in mind that some factories keep Water based as standard, which is why the price for charcoal can be cheaper.

UV-based finishing uses UV light to quickly cure coatings containing photoinitiators, while water-based finishing relies on water as a solvent for the coating. UV finishing offers rapid curing and excellent hardness, while water-based finishing is more environmentally friendly with good durability. The choice depends on application needs and environmental considerations.

From the photo above you can see that the difference is quite visible. On the other hand water-based is slightly cheaper than UV based.

What is the difference between Glossy and Matt finishing

All type of finishing Water based, UV and OPP can be made in Glossy and Matt format

The main difference between glossy and matte finishing lies in their appearance and surface characteristics:

- Glossy Finish:

- Appearance: A glossy finish has a shiny and reflective surface, creating a high-gloss or mirror-like appearance. Light bounces off the surface, making colors appear vibrant and saturated.

- Texture: The surface of a glossy finish is smooth and even, without any visible texture.

- Reflection: Glossy finishes reflect light, which can lead to glare or reflections in certain lighting conditions.

- Stain Resistance: Glossy surfaces are generally more resistant to stains and liquids due to their smoother texture.

- Matte Finish:

- Appearance: A matte finish has a non-reflective, flat surface with a subtle sheen or dullness. It provides a soft and understated appearance.

- Texture: The surface of a matte finish may have a slightly rough or granular feel, which diffuses light and reduces glare.

- Reflection: Matte finishes do not reflect light, making them ideal for spaces with bright lighting or where glare is undesirable.

- Stain Resistance: While matte finishes are less resistant to stains compared to glossy finishes, any stains that do occur are less noticeable due to the lack of reflections.

Simply UV is more shiny and blinky than matt finish. Matt is calm and flat. It is better to consult with our manager to check what kind of finishing is the best for your box design.

What is the difference between UV finishing and OPP Finishing?

OPP stands for Polypropylene (OPP) lamination. It is an additional layer of thin plastic applied to your inner box for color protection.

- OPP lamination involves applying a thin layer of polypropylene film onto the surface of the printed box using heat and pressure. The film adheres to the box, providing a protective and glossy coating.

- Appearance: OPP lamination adds a glossy and smooth finish to the box, enhancing the vibrancy of colors and making the packaging look more appealing.

- Durability: The lamination adds a protective layer that makes the box more resistant to water, dirt, and wear and tear. It also helps prevent fading of the printed design due to UV exposure.

- Finishing Types: OPP lamination is available in both glossy and matte finishes, providing flexibility in the final appearance of the box.

The best way to do finishing is to apply OPP laminating to the box. It is a special layer of plastic applied to the surface of the box. Laminating makes the box looks shiny and protects it from scratches.

Note that if you print “block” color, for example, all black or all grey – it is good to have to laminate and do double color printing. It means that the printer has to print the background color of the box 2 times.

Basically, OPP is the best solution for high-end brands. But it also costs +35 USD additional per ton.

Extra finishing for the inner box

There is a lot of extra finishing for the inner box that can make your design stand out from other brands.

Emboss

We can emboss the inner box.

Emboss means that some part of the box will rise in three dimensions on your box.

For example, you can emboss the logo, to attract more attention to it.

So embossing influence not only visually but also change how you fill while touching the box.

UV Spot

UV spot is a type of printing in which we apply UV Coating to a specific area of the box rather than coating the entire surface.

With UV spot you can emphasize some parts of the boxes to grab more attention.

The best part of the box is usually covered with a matt finish, so the focus UV part spot looks much shinier than the other parts.

UV Spot + Emboss

For the best results, you can cover your logo both with emboss and UV spot.

The price of this box finishing is much higher, but if your customers buy with their “eyes” first, it is the best way to attract their attention.

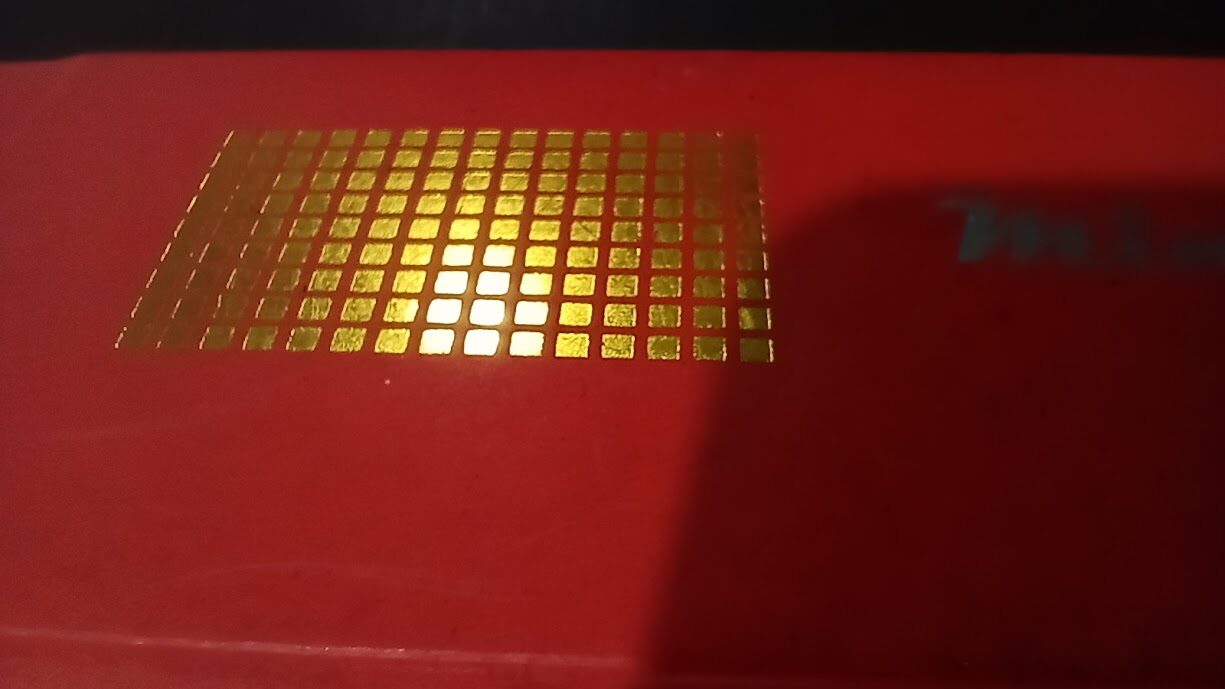

Silver & Gold stamps

One of the most effective ways to grab attention to your hookah coal packaging is to use silver or gold plats on the box.

By default gold and silver plat finishing is already very shiny and you do not need to add any more elements.

We can do any shape or logo you want with silver or gold stamps on the box.

By request, there are several more colors available.

3D hologram

The most exclusive way is to add a 3D hologram to your box.

It will shine, and change color and image if we change the angle of view.

This is also a very good way to protect your charcoal briquettes from forgery. And keep your clients sure that they are buying the original product from you.

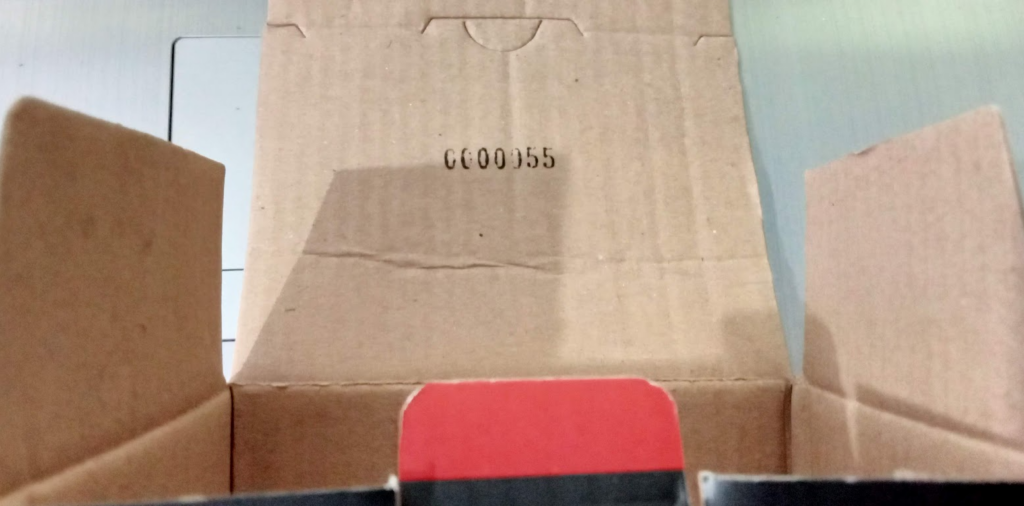

Inner Box Individual Number

Each box produced by our charcoal factory has an individual number. By this number we can track when charcoal was produced, and what mixer was used. In what oven charcoal was dried?

It makes it easy for our quality control team to track back if any quality issues arise. Also, we know who was packing their particular box of shisha coals.

Inner box production time

The longest production time in all charcoal manufacturing processes is making an inner box. Inner boxes are produced by a professional dedicated printing house. Most of our partner printing houses are located in Semarang.

Production time for the inner box is 2-3 weeks after the design is submitted to the printing house. Why so long? Actually, the real printing time is just a couple of hours. All our client’s inner boxes are printed on a professional Heidelberg offset printing machine with 6+1 colors mode. The printing is controlled by electronics and is very fast.

But the printing house does not keep paper for the printing, for each order, the printing house places an order to the paper manufacturer. That is why it consumes a lot of time. For repetitive orders, we can ask the printing house to buy paper in advance, so in this case, printing will take only 3-5 days only.

Multiple colors printing

All inner boxes are printed in the format of 4 colors: cyan, magenta, yellow, and black (CMYK). It is standard for all offset professional printers. With those 4 colors, we can generate millions of color variations. But our printing house support up to 7 colors (6+1) on its Heidelberg machinery. Additional 1-2 colors can be for the special colors, not mixed from CMYK.

Master Box

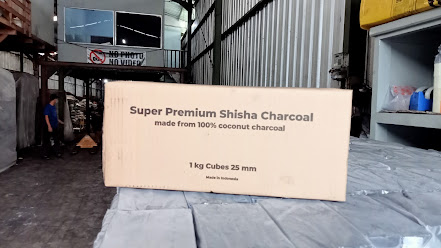

The master box is usually a big brown box made from cardboard B or E flute craft paper. It is used for protecting and handling inner boxes or inner plastics. The most common size is a 10 kg master box that contains 10 inner boxes or 10 inner plastics.

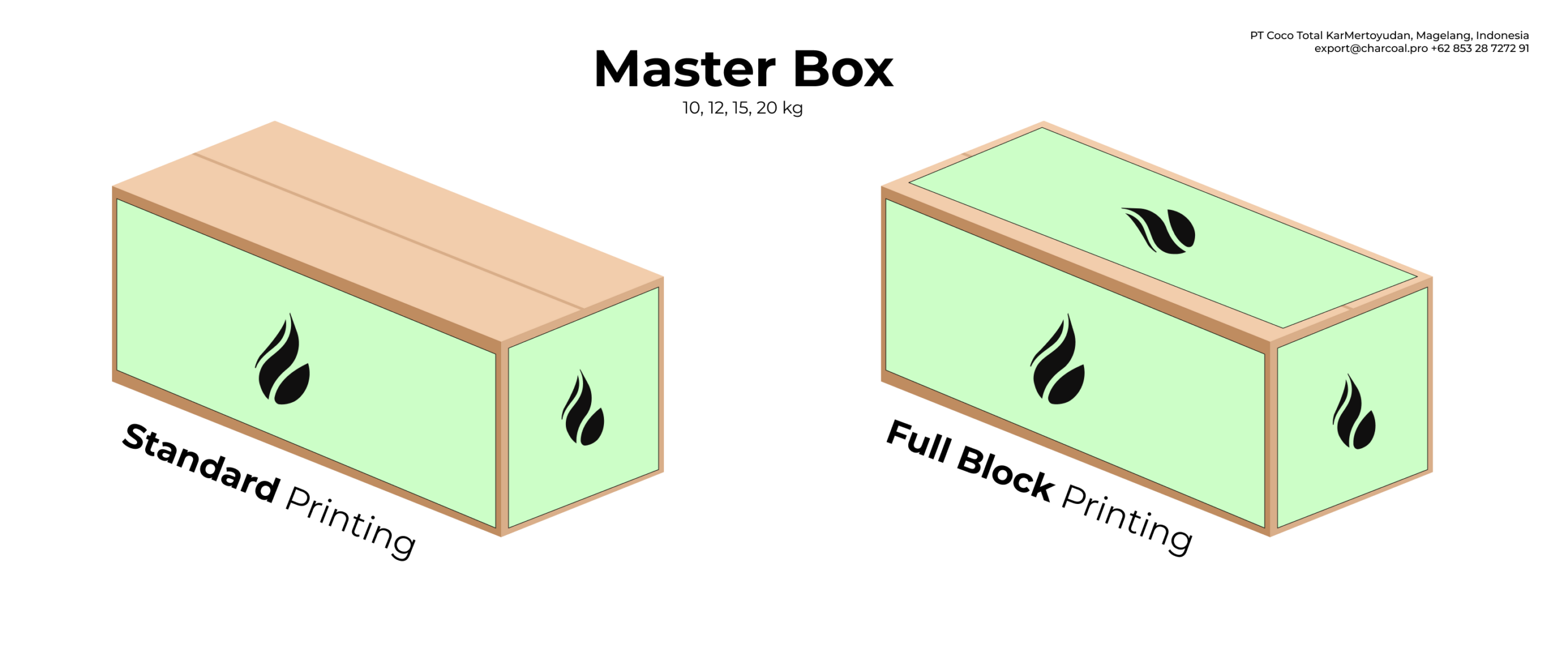

3D visualization of the Master box

We can make 5 kg, 12kg, 16 kg, and 20 kg master boxes. Note, that in most cases the number of the inner box or inner plastic inside one master box should be even numbers like 10, 12, 14, 16 18, and so on.

Master box types

There are 2 main master box types: single wall and double wall. Each wall is made from Craft 150gsm paper as the outer part and Medium liner 125 gsm paper for B flute and the outer layer of the box is again Craft 150 gsm.

Please pay attention that this is our factory standard packaging, but some other factories can use thinner paper like Craft 125gsm instead of Craft 150gsm. That will be cheaper but not as strong as expected.

What is better: a single or double wall box?

The simple double wall box is much stronger but is also thicker and heavier.

We recommend using the double wall only if you buy in bulk packaging without an inner box

As for single walls, it is recommended to use inner box packaging.

Master box layout & size

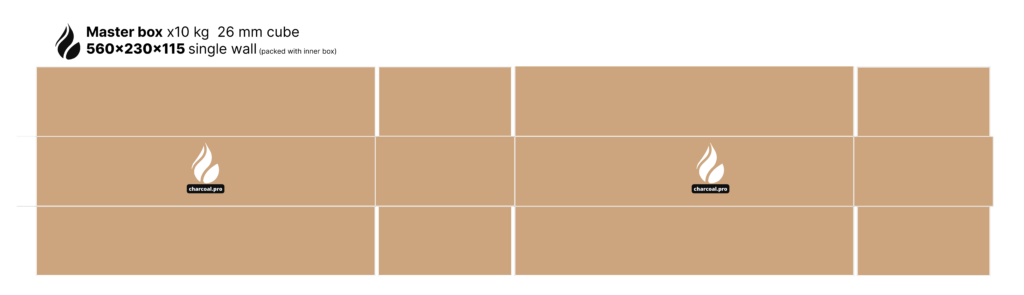

There are several sizes for the master box, the most popular is the 10 kg master box with dimensions:

| Master Box 10 kg Cube 25 mm with 1 kg inner box (single wall) | 415 x 217 x 164 |

| Master Box 10 kg Cube 25 mm with 1 kg inner plastic (bulk) (double wall) | 412 x 215 x 164 |

| Master Box 10 kg Cube 26 mm with 1 kg inner box (single wall) | 560 x 230 x 115 |

| Master Box 10 kg Cube 26 mm with 1 kg inner plastic (bulk) (double wall) | 558 x 228 x 115 |

| Master Box 20 kg Cube 25 mm with 1 kg inner box (double wall) | 417 x 219 x 330 |

For each size and type of master box, we have a layout that can be sent by request.

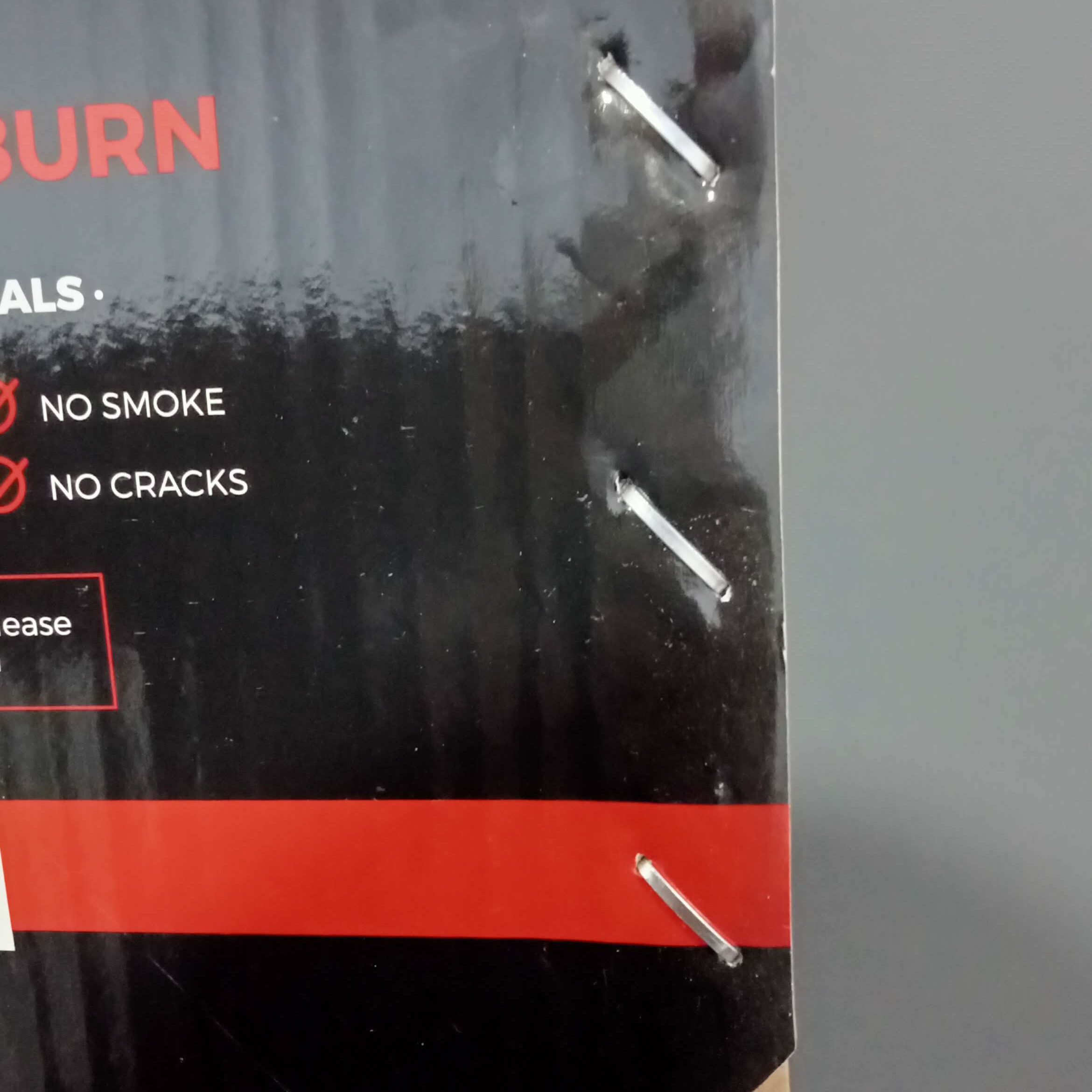

Stapeler vs Glued master box

In most cases, master box sides are fixed with the big industrial stapler. It is a strong and safe method to keep the box as it is. But for small boxes size like 5, 8 or 10 kg we can use glue. The glued box looks nice and clean.

Full block printing on the master box

We can print your brand and design on the master box.

Standard printing is on the sides only. While full block printing is sides + upper and lower side of the box.

Full block printing can be done in full colors. But if you need very precise coloring or you have color gradation, it is better to use not full-block printing but glossy finishing printing.

Standard printing can be done in 3 colors which can make full-color print

Master box finishing

Same as the inner box and master box can have very different finishes on the surface. The standard is just full color (3 colors) roll print on the craft box. But if you want to really stand out from the other brands, some of our clients use UV finishing for master boxes, too. For sure the price of UV finishing is much higher. The standard master box is a roll-printed box on craft paper. While UV finishing is added an additional duplex of 250 gsm is to the outer side of the box.

The finishing can be done both in matt and glossy variants

Duct tape

Since 2025 we have also been able to make duct tape that seals the master boxes with your own brand. In general we use semi-transparent duct tape without brand, but by request we can do it for you. The minimum order is 10000 Master boxes , parox 100 tons of charcoal.

Additional plastic covers

Very often, our charcoal buyers are asking for an additional level of box protection. It can be done by applying shrinkable PE plastic to the master box. It is made with machine shrink.

This plastic helps to protect the master box from moisture and physical damage.

Besides outer shrinkable plastic, we can use big inner master plastic that is inserted inside the master. Box and also protect inner packages from moisture.

Master box strapping band

Strapping is important to secure transportation. If you deliver coconut charcoal to Europe or the USA – is ok not to use strapping.

If you are planning to bring the container of charcoal far from a port,

Use a lot of trucking and restaffing, so strapping is strongly recommended.

Strapping secure charcoal boxes position so it would “run” inside the container.

What is the cost of strapping per tonne?

Strapping is crucial for securing cargo during transportation, especially when it’s a long journey with multiple transfers. If you’re delivering coconut charcoal to destinations within Europe or the USA and the distance from the port is short, you might not need strapping. However, for deliveries that involve extensive trucking and multiple handling points, strapping is highly recommended to prevent the charcoal boxes from shifting inside the container.

The cost of strapping is $8 per tonne. It provides an additional layer of security to ensure the cargo arrives safely at its destination.

When is Strapping Recommended for Shipping Coconut Charcoal Briquettes?

Strapping is a crucial step in securing your coconut charcoal briquettes during transportation. If your shipment is destined for Europe or the USA and involves direct port-to-port delivery, strapping may not be necessary. However, if your cargo will travel a significant distance from the port, particularly when extensive trucking or multiple transfers (restaffing) are involved, strapping becomes essential.

Proper strapping ensures that the charcoal boxes remain securely in place, preventing them from shifting or “running” inside the container. This helps maintain the integrity of the shipment, minimizing the risk of damage during transport.

In summary, always consider strapping when your charcoal briquettes will undergo long-distance transportation, multiple handling processes, or extensive trucking to reach their final destination.

What is the purpose of strapping coconut charcoal boxes?

The Purpose of Strapping Coconut Charcoal Boxes

Strapping is crucial for ensuring the safe and efficient transportation of coconut charcoal boxes. Its primary function is to secure the boxes in place during transit, preventing movement that could cause damage.

When transporting coconut charcoal over long distances or involving numerous transfers, such as trucking and restaffing, the risk of boxes shifting increases. Strapping minimizes this risk by keeping the boxes firmly positioned, reducing the likelihood of any internal “running” or shifting within the container.

For shipments that extend beyond the port and involve complex logistics, strapping becomes even more essential. This added layer of security helps maintain the integrity of the product throughout its journey.

While the cost of strapping is approximately $8 per ton, this investment is small compared to the potential losses from damaged goods. In sum, strapping ensures that your coconut charcoal arrives at its destination in optimal condition, regardless of the distance or handling required.

Master box automatic sealing

All our master boxes are sealed with an automatic tape-sealing machine. It helps to make the box nite and clean.

Master box production time

All master boxes are printed the same as inner boxes at dedicated offset printing houses. But in most cases, they are different from the inner box printing houses. Production time take 7-12 day on average 10 working days for printing.

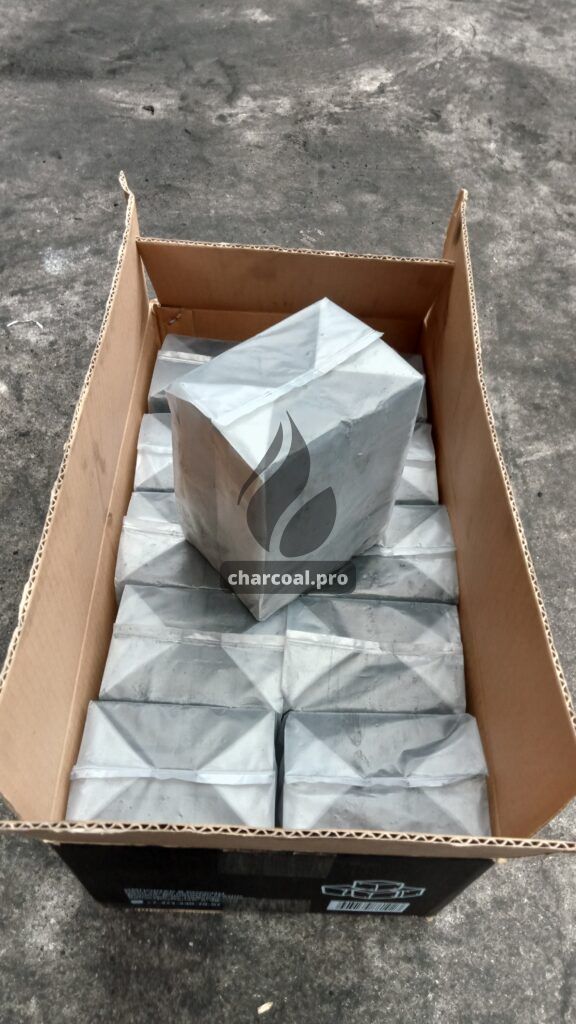

Bulk packaging

Bulk packaging of coconut charcoal means that we are not using the inner box. It saves our customers about 100 USD per ton. Bulk packaging is the best way if you supply to HoReCa and clients do not care about the inner box.

With bulk packaging, coconut charcoal is packed directly into the master box.

The master box is a corrugated brown colored carton box. The main function of the master box is to protect your charcoal from physical damage and make it easy to carry and store of charcoal.

There are two main variants of bulk packaging:

- packaging with one big inner plastic then to the master box. It can be packed and arranged inline or it can be just bulk.

How long does it take to pack coconut charcoal into inner boxes?

Packing coconut charcoal into inner boxes typically requires a time frame of 1 to 2 days. This period ensures that the charcoal is securely and properly placed, maintaining the product’s quality and integrity.

How long does it take to print inner boxes for coconut charcoal briquettes?

To print inner boxes for coconut charcoal briquettes, you should plan for a timeline of approximately 5 to 10 days. It’s important to submit your inner box design to the charcoal factory as soon as possible to avoid delays. Once the printing is complete, the process of packing the charcoal into the printed inner boxes typically takes an additional 1 to 2 days.

How can buyers save money by ordering coconut charcoal without the inner box?

How Can Buyers Save Money by Ordering Coconut Charcoal Without the Inner Box?

Opting for coconut charcoal without the inner box can lead to substantial cost savings for buyers. Here’s how:

- Reduced Packaging Costs: When you choose charcoal packed in transparent plastic, you eliminate the need for the additional inner boxes. This reduction in packaging material directly translates to cost savings.

- Lower Freight Charges: By reducing the overall weight and volume of the shipment, the freight costs are significantly lowered. This is especially crucial when shipping large quantities, such as a 20-foot container.

- Streamlined Handling: Without the inner boxes, loading and unloading the charcoal become more efficient. This can save both time and labor costs.

In fact, you can save up to $1,950 per 20-foot container by foregoing the inner boxes. These savings can then be reinvested into other areas of your business, increasing your overall profitability.

How can you get your brand & label on coconut shell charcoal for shisha & hookah?

As a charcoal factory – we meet many clients. Most of them are asking to make charcoal under their own brand names.

Our basic manufacturing policy is making charcoal under the client’s brand. We do OEM, private-label charcoal.

The first step to ordering charcoal under your name is to check if this brand is a registered trademark or not. For example, if you want your charcoal name to be Coco Urth or Nara, or Tomcoco – it is all registered brand names.

To make it under those names you have to prove to us that you are the owner and sign related documents.

If your brand name is not under the registered trademark – we can do it right away.

The second step is to send us your design in the format of .pdf or .ai. We will bring it to the box manufacturer to make a sample design and adjust the size of the boxes.

The third step is to find and agree on the specifications of the actual product. What is the ash content and ash color, what is the max moisture level and burning time? All this we have to discuss and agree on.

The fourth step is the actual production of coconut shell charcoal and the printing of your branded packaging.

Besides doing branded packaging we can add stickers on the inner plastic. Do the printing of your brand on the inner plastic. Do the full-color printing on the master box.

Process of Production

The inner and Master box printing process consists of the following steps:

- first, we send you the layout of the box with the sizes

- your designer makes the initial design

- we make checks of boxes including Trade Mark checking

- design is sent to the printing house for size adjustment

- printing house makes a digital print of the box for the approval

- by request, we can print not just a digital sample but an offset real sample of the boxes

- after final approval by the buyer, we process mass production of the packaging

- packaging is delivered to your charcoal factory

- our house quality control performs color, size, and quality checks of the boxes

- we do packaging and storing ready-packed boxes.

important to note, all designs are being checked for Trade Mark registration. We also recommend to register your unique brand name with us to prevent from copies.

Requirements for the boxes

Important to note that all boxes shall contain the following information:

- Made in Indonesia

- Imported by (your importing company name)

- For Russian Federation: Date of production

- не подлежит обязательной сертификации

- не подлежит обязательной оценке соответствия

- срок годности не ограничен

- Safety measurements

Difference between bulk loss, bulk, and full packaging

Basically, there are 3 types of packaging available for coconut charcoal briquettes.

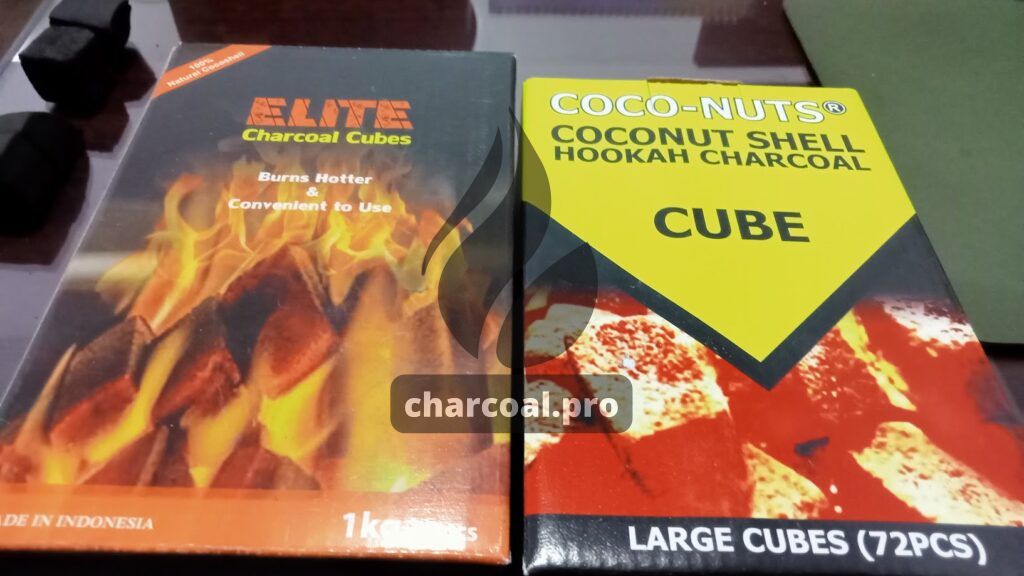

Full packaging

Full packaging means that your coconut charcoal will be packed inside inner plastic + inner box + master box

The primary size is 1 kg for the inner plastic and 1 kg for the inner box + 10 kg master box.

The packaging will look like this but with your own brand.

This packaging is the perfect solution if you sell through the shops to the end buyer or smokers who will use it at home.

Basically, if the buyer is buying a product with “eyes” first, like seeing your product on a shopping shelf, it is the best choice. But if you just sell to bars, lounges, and hookah restaurants, where the end-user is not seeing the brand, it is recommended to take bulk packaging.

Bulk packaging

Bulk packaging means your coconut charcoal briquettes will be packed in 1 kg of inner plastic and put inside the master box.

So basically it is similar to complete packaging but without an inner box. It makes packaging cheaper at about 100 USD per ton. Good safe for wholesale hookah coal distributors, right?

This type of packaging is cheaper and is the perfect solution if you sell to bars and restaurants. With bulk packaging, you are not spending too much money on unnecessary box branding.

More you can load about 600 kg more into a container due to the smaller package.

Bulk loose packaging

Bulk loose packaging is very similar to normal bulk packaging, but we just put all charcoal bulk inside one big plastic bag and inside the master carton.

So, for the bulk packaging, we pack inside 1 kg inner plastic bag, while for bulk lose we pack inside one big plastic bag.

This is the perfect solution to save maximum cost on the packaging. Good for high-volume wholesale buyers who distribute charcoal to big bars and hookah lounges.

What are the benefits of using pallets to ship coconut charcoal briquettes?

Benefits of Using Pallets for Shipping Coconut Charcoal Briquettes

When considering the shipping of coconut charcoal briquettes, using pallets can offer some notable advantages:

- Ease of Handling: Pallets simplify the unloading process at your warehouse. With the right equipment, forklifts can efficiently remove boxes from the container, reducing manual labor and speeding up operations.

- Orderliness: Pallets help keep the boxes orderly and secure during transit, minimizing the risk of goods shifting, which can potentially lead to damage. This ensures that your charcoal briquettes arrive in optimal condition.

- Fumigation Requirements: If you’re using wooden pallets, they generally come with a fumigation certificate and stamp. This can be a regulatory advantage in certain regions that require proof of pest control, facilitating smoother customs clearance.

However, it’s worth noting that pallets do consume additional space within the container. This means that while you’ll experience easier unloading and potentially better organization, you may fit fewer boxes overall. Specifically, without pallets, you can load approximately 1820 boxes, but with pallets, the number drops to around 1650 due to the extra space they occupy.

In summary, utilizing pallets for shipping coconut charcoal briquettes brings efficiency and ease to handling and unloading, albeit at the cost of reduced cargo capacity.

Why is it not recommended to use pallets when shipping coconut charcoal briquettes?

Why Should You Avoid Using Pallets When Shipping Coconut Charcoal Briquettes?

When it comes to shipping coconut charcoal briquettes, avoiding the use of pallets can offer significant advantages:

Maximize Space Utilization: Using pallets consumes valuable space within the shipping container. Without pallets, you can load up to 1820 boxes. However, with pallets, you’re limited to just 1650 boxes. This means you lose the capacity for an additional 170 boxes—a considerable difference.

Reduce Additional Requirements: Shipping without pallets simplifies the process. If you choose to use wooden pallets, the manufacturer must provide a fumigation certificate and stamp each pallet. These steps add time and complexity, which might delay your shipments.

Efficiency in Unloading: While pallets can make unloading more straightforward once the shipment arrives, the overall gains in space and reduced logistical hurdles often outweigh this convenience. The extra space saved allows you to transport more product per shipment, making your operations more efficient and cost-effective.

In summary, skipping pallets when shipping coconut charcoal briquettes helps you maximize container space and remove extra procedural steps, contributing to a smoother and more efficient shipping process.

FAQ

Can you do packaging with my brand?

Certainly! If you are interested in customized packaging with your customer’s brand, we’d be more than happy to assist you in creating the perfect layout and box sizes. We take pride in offering this service to our valued wholesale buyers.

Please feel free to get in touch with us to discuss your specific requirements and preferences for the packaging design. Our team is well-versed in creating attractive and eye-catching packaging that showcases your brand in the best possible way.

It’s essential to note that we always prioritize the protection of your brand and intellectual property rights. As a standard practice, we run a trademark check for all custom packaging to ensure that it complies with legal requirements and safeguards your brand identity.

To proceed with the customization process or to inquire further about our packaging options, please don’t hesitate to contact us. You can reach us via WhatsApp at +628118797070 or email us at export@charcoal.pro.

We look forward to working with you to create packaging that truly represents your brand and meets your shisha charcoal business needs. Thank you for considering us as your trusted supplier.

Please let us know if you have any other questions or if there’s anything else we can assist you with. We’re here to provide you with the best wholesale coconut charcoal briquettes and top-notch packaging solutions.Can you do packaging with another famous brand?

No, it is strictly not to copy other brands that do not belong to you. As a manufacturer and supplier of wholesale coconut charcoal briquettes, we are committed to upholding ethical business practices and respecting intellectual property rights. We understand the importance of protecting famous brands and their trademarks.

When it comes to packaging with another famous brand, we need to be cautious and ensure that we have the proper authorization and licensing to do so. Using another brand’s logo, name, or trademark without permission can lead to legal consequences and damage the reputation of all parties involved.

If you are interested in co-branding or using another famous brand’s imagery on the packaging, we recommend reaching out to the brand owners directly to discuss the possibility of a collaboration or licensing agreement. This approach ensures that all parties involved are aware of and agree to the usage of the brand in a mutually beneficial and legal manner.

As a responsible business, we are more than willing to work with you and any other brand owners to explore co-branding opportunities or licensing agreements, provided that all necessary permissions and legal requirements are met.

If you have any specific brands in mind or if you would like us to assist you in approaching brand owners for potential collaborations, please let us know. We are here to support you in creating a successful and legally compliant packaging solution for your wholesale coconut charcoal briquettes.

Feel free to contact us via WhatsApp at +628118797070 or email us at export@charcoal.pro to further discuss your packaging needs and explore the possibility of co-branding or licensing arrangements. Thank you for your understanding and cooperation in this matter.Can you do environmentally safe boxes?

Absolutely, we prioritize environmental sustainability and are committed to providing environmentally safe packaging options for our wholesale coconut charcoal briquettes. We understand the importance of minimizing our ecological footprint and contributing to a greener future.

When it comes to packaging, we offer several environmentally friendly options to choose from:

Recyclable Cardboard Boxes: We use recyclable cardboard material for our packaging, ensuring that the boxes can be reused or easily recycled after use. This helps reduce waste and promotes a more sustainable packaging solution.

Biodegradable Kraft Paper Bags: For customers who prefer a more natural packaging option, we offer biodegradable kraft paper bags. These bags are made from renewable resources and can break down naturally over time, reducing their impact on the environment.

Eco-Friendly Polypropylene Bags: In case you need more robust protection for the charcoal, we also offer eco-friendly polypropylene bags that are designed to be durable and moisture-resistant. These bags are made with environmentally conscious practices in mind.

Reusable Plastic Containers: If you prefer a reusable option, we provide plastic containers that are designed for multiple uses. These containers are made from recyclable materials and are perfect for customers who aim to minimize single-use packaging waste.

As an environmentally responsible company, we continuously strive to improve our packaging practices and explore new eco-friendly alternatives. We firmly believe that by offering environmentally safe packaging, we can contribute to a cleaner and healthier planet.

If you are interested in any of our environmentally friendly packaging options or have specific preferences in mind, please let us know. We are here to accommodate your needs and ensure that your wholesale coconut charcoal briquettes are packaged sustainably.

Feel free to contact us via WhatsApp at +628118797070 or email us at export@charcoal.pro to discuss your requirements and explore our range of environmentally safe packaging choices. Thank you for choosing an environmentally conscious approach to packaging, and we look forward to working with you.What if the box will be damaged during shipping?

At our company, we take extensive measures to ensure that our boxes remain intact and undamaged throughout the shipping process. Firstly, our expert team packs the boxes in a manner that prevents any movement within the container. This means that your boxes will remain stable and secure during transit, eliminating the risk of them shifting or “walking” along the container.

Secondly, before loading the boxes into the container, we conduct thorough checks to ensure that each box is in pristine condition and free from any defects. This ensures that only clean and structurally sound boxes are included in the shipment.

Moreover, we always keep additional spare boxes readily available in the event that any replacements are required during the shipping journey. This proactive approach guarantees that we can swiftly address any unforeseen issues that may arise.

To provide an extra layer of protection, all boxes inside the containers are covered with plastic. This plastic covering shields the boxes from moisture, safeguarding the integrity of the packaging and its contents.

Furthermore, we incorporate container-size moisture absorbers to provide additional protection against humidity and moisture. This precautionary measure further ensures that the boxes and the enclosed coconut charcoal briquettes remain in optimal condition, even when exposed to varying weather conditions.

Rest assured that our comprehensive packaging and shipping practices are designed to minimize the risk of box damage and deliver our premium wholesale coconut charcoal briquettes to you in perfect condition. Your satisfaction and the safety of your order are our top priorities.

If you have any further questions or concerns regarding our packaging and shipping procedures, please do not hesitate to reach out to our team. We are dedicated to providing you with the best possible service and product quality.Can the factory print my brand logo and design on the packaging

Absolutely, we’re all about customizing your packaging to reflect your brand. As an OEM charcoal manufacturer, we specialize in creating products with your unique brand identity. That means we can print your logo and design on all the packaging, including inner boxes and master boxes.

Just shoot over your design, and we’ll take care of the rest. If you need it, we can even provide you with the layout and dimensions of the boxes. For instance, we have cube options like 25mm or 26mm, so your designer can tailor the design to fit perfectly.Are there limitations on the size or placement of the logo

Regarding the logo size and placement, there aren’t any strict limitations. As long as the size fits within the dimensions of the packaging, we’re good to go. For instance, with the inner box like Cube 25 mm for 1 kg, where the box height is 21 cm, your logo should comfortably fit within the box layout.

Placement-wise, as long as it’s on a visible part of the box, we’re all set to print it. However, just a heads up, we typically don’t print on the inner part of the box, even though it’s technically feasible.Are there any restrictions on the number of colors or design complexity for custom branding

Your inner boxes undergo professional mass production printing using offset printing methods. This means your inner box can feature full-color printing with essentially an unlimited number of colors. Offset printing typically involves 4-color printing machines, operating in CMYK mode. This process involves applying different colors in 4 to 6 passes, resulting in a mix of colors that create your unique box color.

While most colors can be achieved through CMYK mixing, some shades may require special colors produced specifically for your brand at the color factory. This ensures color consistency across all boxes. However, it’s essential to note that while there’s no basic design limitation, intricate designs with small parts may not always be feasible for printing. Think of intricate details like those found on banknotes; reproducing such complexity on a box may not be possible.

If you require specific colors like silver or gold, they can be achieved either through standard CMYK mixing or by using special “real” gold paint.

When it comes to master boxes, typically containing 10 to 20 kgs of charcoal, they’re printed in a separate printing house specialized in cardboard printing. These facilities usually employ roll printing machines and standardize on 3 colors. Achieving very sharp, colorful designs on master boxes can be challenging. However, if you desire a glossy, colorful finish, you can opt for duplex finishing paper instead of craft paper, though this option comes with additional costs.

To ensure feasibility, I always recommend clients to share a draft design of the future box so we can confirm everything is printable.What is the cost of full-color labeling per tonne?

For full-color labeling, the cost is $9 per tonne. You provide your label design, and we handle the printing and application on the boxes.

What is the cost of printing the inner box for shisha charcoal in Indonesia?

The cost of printing the inner charcoal box in Indonesia ranges between $1 and $1.50 per kilogram.

Who is responsible for the design and layout of the inner box for coconut charcoal briquettes?

The responsibility for designing and laying out the inner box for coconut charcoal briquettes falls on the buyer. The buyer determines the branding, color scheme, and dimensions of the box. It is important to note that the charcoal factory itself does not handle the printing or design work for the inner boxes.

How many kilograms of coconut charcoal can a 20-foot container carry with pallets?

1 x 20ft container holds 18200kgs of charcoal or 1820 Master Boxes without pallets. If you are using pallets 1 x container can hold 16500kgs of coconut charcoal or 1650 Master Boxes on pallets.

How many kilograms of coconut charcoal can a 20-foot container carry without pallets?

A 20-foot container can hold 18,200 kilograms of coconut charcoal without using pallets.

How Are Coconut Charcoal Briquettes Shipped?

Coconut charcoal briquettes are primarily transported by sea, utilizing standard 20-foot containers. These containers can carry either 18,200 kilograms of charcoal or 1,820 Master Boxes when shipped without pallets.

If the use of pallets is preferred, the capacity slightly changes. A container with pallets can hold up to 16,500 kilograms of charcoal or 1,650 Master Boxes. It’s important to note that the cost of the pallets is an additional expense borne by the buyer.

Overall, the shipping method is designed to maximize efficiency while offering flexibility depending on whether or not pallets are used.How many cubes of charcoal are in 1 kg of coconut charcoal?

One kilogram of coconut charcoal cube size 25 mm contains 72 individual charcoal cubes.

for cube 26 mm is 64 pcs per kg

for cube 27 mm is 54 pcs per kgWhat are the common sizes for cube-shaped coconut charcoal briquettes?

The common sizes for cube-shaped coconut charcoal briquettes typically include 25x25x25 mm, 26x26x26 mm, 27x27x27mm and 22x22x22 mm.

What shapes do coconut charcoal briquettes come in?

Coconut charcoal briquettes are available in a variety of shapes to suit different preferences and uses. The most popular shape is the cube, typically in sizes such as 25x25x25 mm and 22x22x22 mm. Additionally, these briquettes can be found in round, flat, and hexagonal forms, offering multiple options for those who enjoy shisha or hookah.

What is the importance of labeling for coconut charcoal boxes?

Plastic Screen Printing for Coconut Charcoal Briquette Packaging

Plastic is not only good for your charcoal but also for your branding. We can print color brand on inner plastic. This is very important as many countries require labeling on boxes to meet regulatory standards so your product comply with international sales requirements.

Printing is counted based on several colors. Most of the clients are using one or two colors of screen printing but we are not limited and can use up to 15 colors on the same plastic. Here are some options to consider:

Plastic screen printing for coconut charcoal briquette packaging in single color

Plastic screen printing for coconut charcoal briquette packaging in multiple colors

Print screen for coconut charcoal briquette packaging on inner plastic

Please note that most charcoal factories including ours provide basic labeling for free, full color labeling has additional charge. If the label is full color we charge $9 USD per tonne.

Buyers can send their label design and we will print and apply it to the boxes. This will not only make your product look good but also comply to international labeling requirements.

Please remember that printing on plastic will take additional time, usually 2-3 weeks. So please reserve enough time before ordering this type of packaging to ensure all requirements are met.What are the two main types of master boxes for coconut charcoal briquettes?

Logo size and placement is not limited.

As long as it fits within the packaging, we’re good to go. For example, with the inner box like Cube 25 mm for 1 kg, where the box is 21 cm high, your logo should fit within the box layout.

Placement wise, as long as it’s on a visible part of the box, we’re good to print it. But just a heads up, we don’t usually print on the inner part of the box even though it’s possible.

Your inner boxes are mass produced using offset printing. This means your inner box can have full color printing with almost unlimited colors.

Offset printing uses 4 color printing machines that operates in CMYK mode. This process involves 4 to 6 passes of different colors to mix and create your box color.

While most colors can be achieved through CMYK mixing, some shades may require special colors to be produced specifically for your brand at the color factory. This ensures color consistency across all boxes. But just a heads up, while there’s no basic design limitation, intricate designs with small parts may not always be printable.

Think of intricate details like those found on banknotes; reproducing such complexity on a box may not be possible. If you need specific colors like silver or gold, they can be achieved through standard CMYK mixing or by using real gold paint.

Master boxes that contains 10 to 20 kgs of charcoal are printed in a separate printing house that specializes in cardboard printing. These facilities uses roll printing machines and standardizes on 3 colors. Printing very sharp and colorful design on master boxes is challenging.

But if you want glossy and colorful finish, you can opt for duplex finishing paper instead of craft paper but this will add extra cost.

To confirm feasibility, I always advise clients to send a draft design of the box so we can check if everything is printable. Also, choose the right master box for your needs. We have two types:

Single-wall master boxes: more cost effective but less protection and strength compared to others.

Double-wall master boxes: stronger boxes that provides better protection for the contents. But costs around $60 more per ton than single-wall boxes.

Holidays That Impact Charcoal Production and Shipping

Holidays play a big role in when we can produce then pack and ship charcoal. In Indonesia, Eid marks a major holiday at the end of Ramadan. During Eid, many businesses take a break. For instance, in 2024, the holiday spans from April 5th to April 15th, totaling 10 days off.

During Eid, the government prohibits container trucking. So, the last day to stuff containers in April is the 4th, and trucking resumes on the 15th. Additionally, offices, customs at ports, and the ports themselves shut down. That means that printing houses cannot send us the packaging during this time.

Despite work being set to resume on April 15th, many workers might not return until later. This means work may not pick up until April 22nd or later.

If you’re planning a visit to our factory or shipping during this time, please keep in mind this extended holiday, as it significantly affects our production, packing, and shipping schedules.